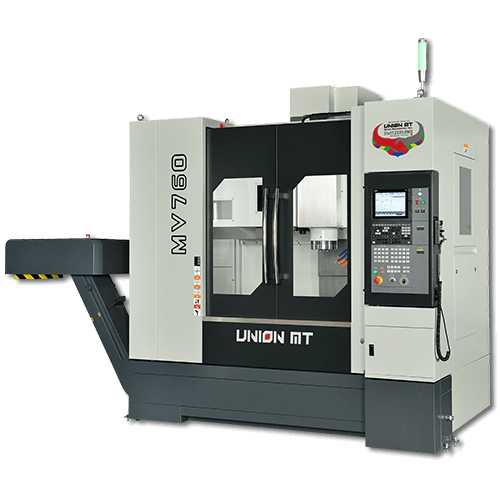

Our Products

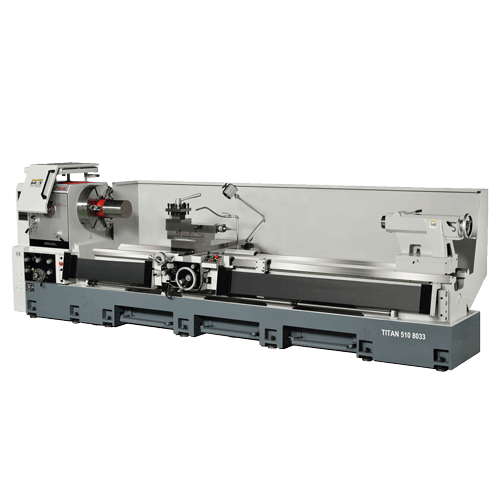

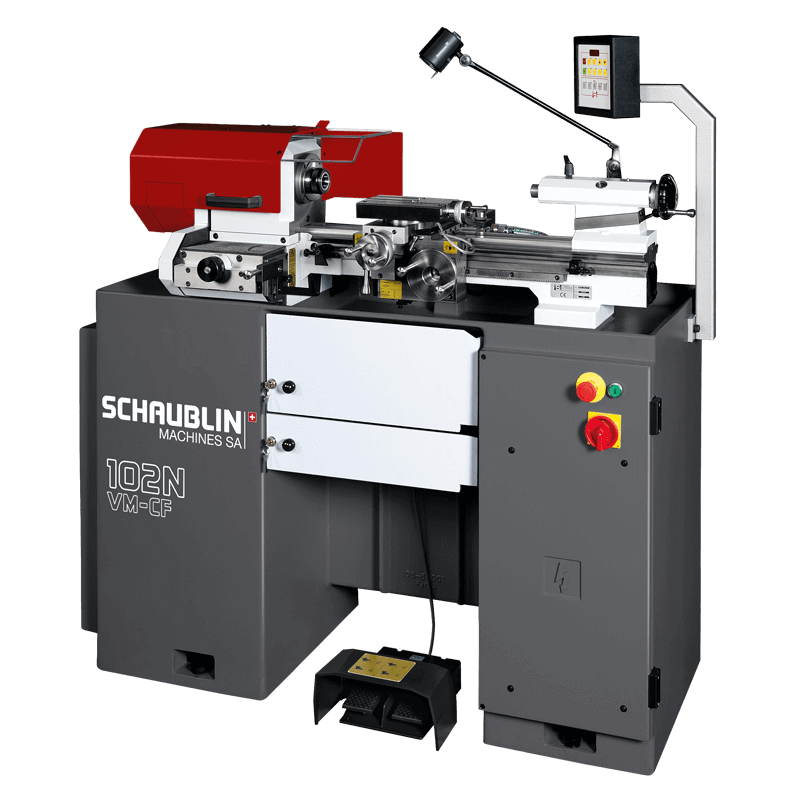

Union MT provides a variety of efficient and precision machining solutions, including CNC Lathe Machine, Multi Spindle Machine, 5 Axis Machining Center, Vertical Machining Center, CNC Horizontal Turning Center, Flat Bed Lathe and Ultra Precision Products.

These solutions are widely applicable in aerospace, automotive, electronics, small and medium-sized parts, and medical industries.

Whether you have high-efficiency precision machining needs or high-volume production requirements, we combine advanced technology and optimized design to deliver the best solutions for you.

Would you consider customising machines?

Leave us a message. We will present our offer to you.

Contact Us