Vertical Machining Center

MV300 / 500 / 600 / 700#30

Machining Capability

Drilling and Tapping

Application

-

-

-

-

-

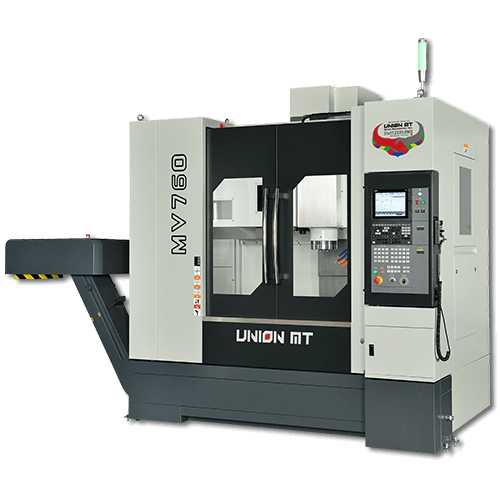

The High Speed Vertical Machining Center MV300/500/600/700 series features the largest working range along with a compact footprint design, making it suitable for both large and small-scale machining operations.

Additionally, these MV models are proficient in accuracy, reliability, and scrap reduction, making them an excellent choice when executing high precision work.

For clients specifically seeking a Small Vertical Machining Center, the MV300/500/600/700 series then offers the advantage of a compact size without compromising on performance or precision.

- High acceleration rates 1.5 G

- Machine stiffness >

2.5 kgf/um - 60 m/min rapids

- Spindle technology up

to 15,000-40,000 rpm

Rigid and Longevity Spindle Technology

Germany KTR, highly efficient thermal isolated coupling, is used to reduce potential heat transfer, vibration and noise featuring higher accuracy and stability.

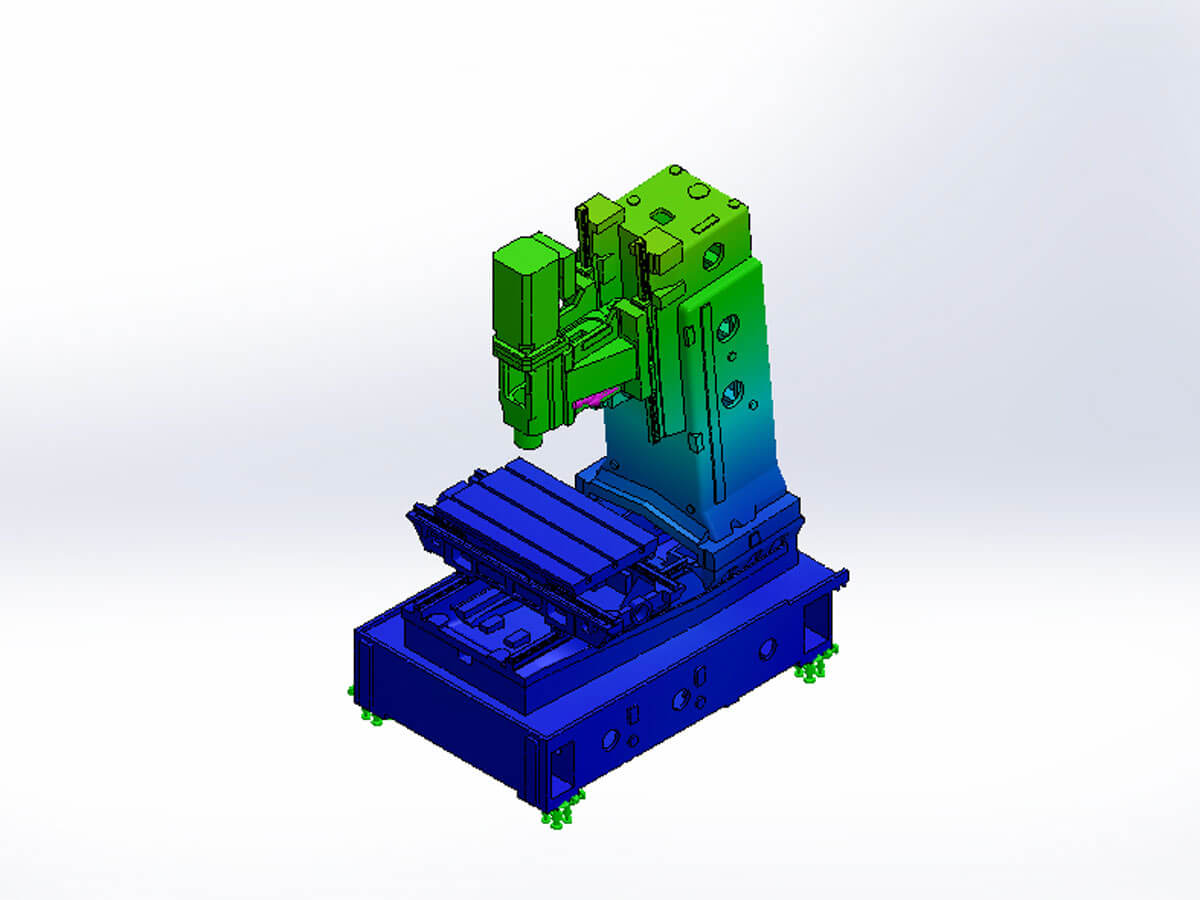

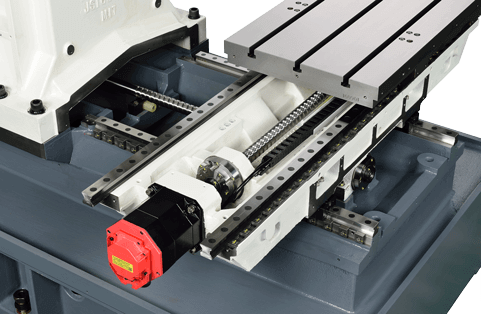

Robust Machine Structure

Heavyduty and high precision roller linear guides 30/ 30/ 30 mm on X/Y/Z axis and preload 32 mm diameter ball screws for transmission rigidity can provide heavyduty machining and stability.

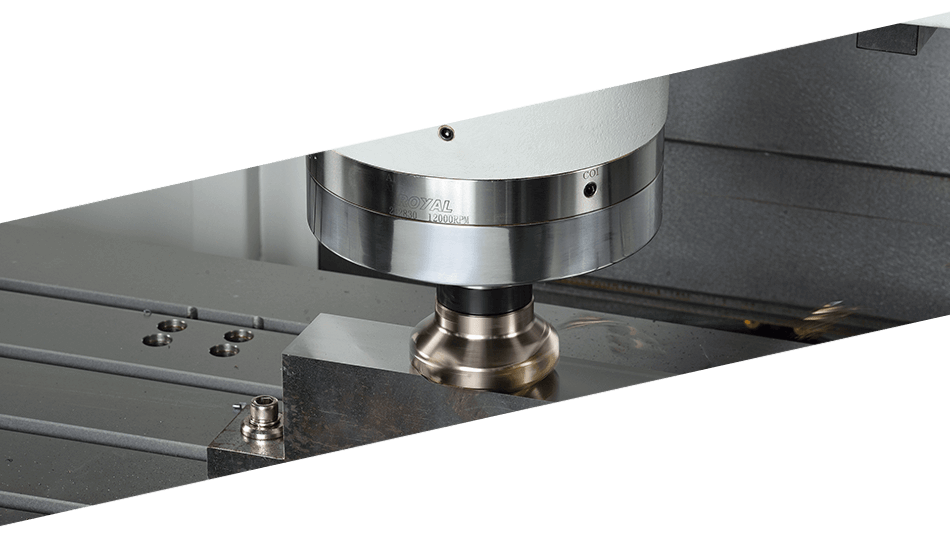

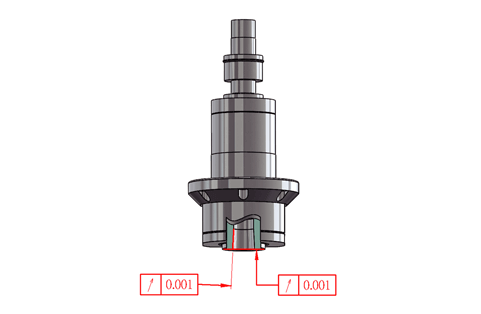

Reliable DDS- Direct Drive Spindle

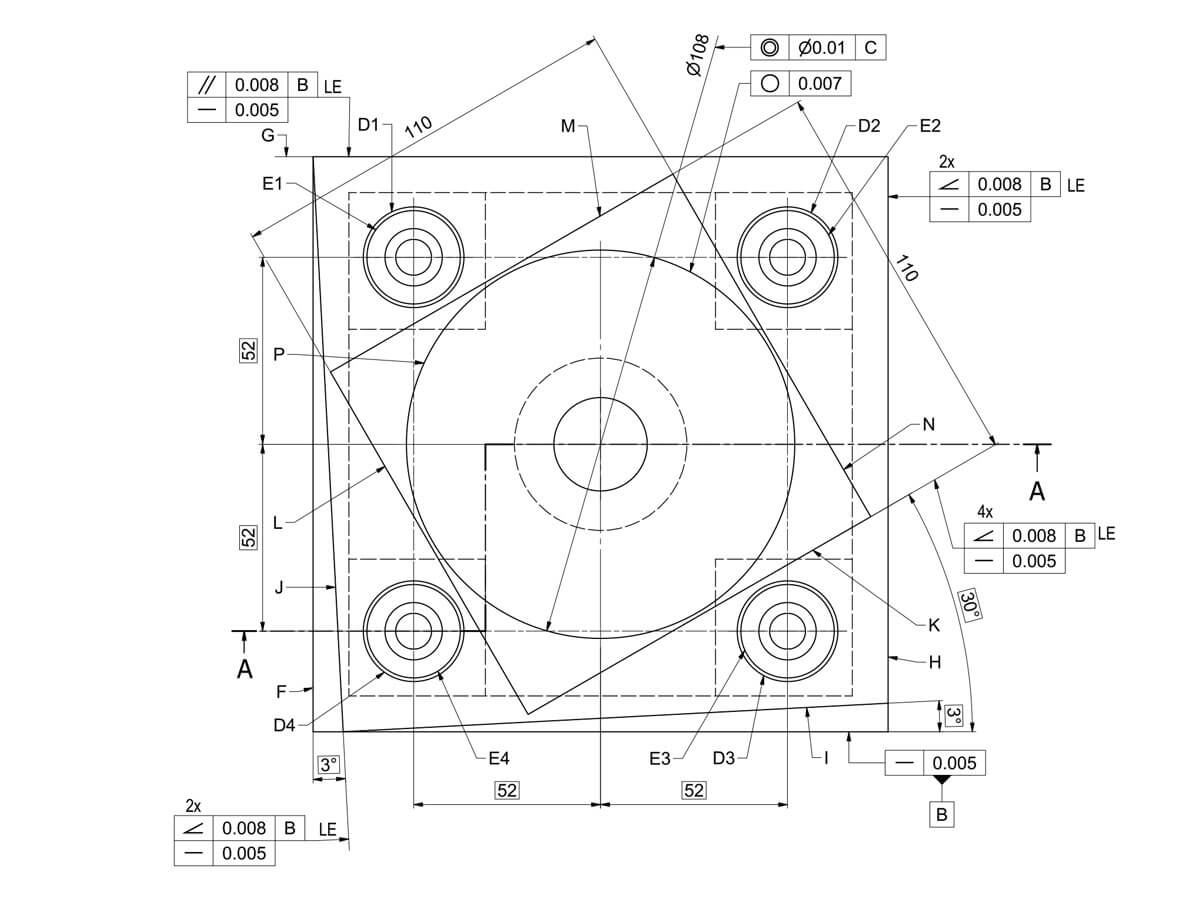

Spindle nose run out 0.001 mm and 0.006 mm at measuing length 250 mm of test mandrel.

Specification

| P Specifications | M Specifications | |||||

|---|---|---|---|---|---|---|

| ITEM | 500P | 600P | 700P | 300M | 500M | 700M |

| Working Range | ||||||

| Travel X | 500 mm | 600 mm | 700 mm | 300 mm | 500 mm | 700 mm |

| Travel Y | 400 mm | 400 mm | ||||

| Travel Z | 330 mm; 450 mm (Swing Arm) | 330 mm; 450 mm (Swing Arm) | ||||

| Spindle nose to table surface | 150~480 mm; 150~600 mm (Swing Arm) | 150~480 mm; 150~600 mm (Swing Arm) | ||||

| Table size | 650 x 410 mm | 750 x 410 mm | 850 x 410 mm | 650 x 410 mm | 850 x 410 mm | |

| Table load capacity | 250 kg | 280 kg | 300 kg | 200 kg | 250 kg | 300 kg |

| T slot width/ qty/ pitch | 14 mm/ 3/ 125 mm | 14 mm/ 3/ 125 mm | ||||

| Main Spindle | ||||||

| Spindle type | BBT30/ HSK A40 Coupling | BBT30/ HSK E40 | BBT 40, Coupling | HSK E40 Built-in Spindle | ||

| Max. spindle speed | 15,000 rpm | 24,000 rpm | 15,000 rpm | 24,000 rpm | 40,000 rpm | |

| Max. spindle output*¹ | Mitsubishi 15 Kw *¹ Fanuc 15.6 Kw *² |

Mitsubishi 18 Kw *¹ Fanuc 20 Kw *² |

Mitsubishi 15 Kw *¹ Fanuc 15.6 Kw *² |

Mitsubishi 18 Kw *¹ Fanuc 20 Kw *² |

18 Kw S6 40% | |

| Max. spindle torque | Mitsubishi 84.3 Nm *³ Fanuc 49.7 Nm *4 |

Mitsubishi 21.5 Kw *¹ Fanuc 21.2 Kw *² |

Mitsubishi 84.3 Kw *¹ Fanuc 49.7 Kw *4 |

Mitsubishi 21.5 Kw *¹ Fanuc 21.2 Kw *² |

7.1 Nm S6 40% | |

| Feed Drive | ||||||

| Feed force X/Y/Z | Mitsubishi 4,712/ 4,712/ 4,712 N Fanuc 3,141/ 4,712/ 4,712 N |

Mitsubishi 4,712/ 4,712/ 4,712 N Fanuc 3,141/ 4,712/ 4,712 N |

||||

| Rapid travel X/Y/Z | 60/ 60/ 60 m/ min | 60/ 60/ 60 m/ min | ||||

| Acceleration X/Y/Z | 1.5/ 1.5/ 1.5 G | 1.5/ 1.5/ 1.5 G | ||||

| Linear guide size | 30/ 30/ 30 mm | 30/ 30/ 30 mm | ||||

| Ball screw diameter | 32 mm | 32 mm | ||||

| Automatic Tool Changer | ||||||

| Tool selection | Random and shortest selection | Random and shortest selection | ||||

| Magazine pots | 20 (Turret), 21 (Servo Turret), 20 (Swing Arm) | 20 (Turret), 20 (Swing Arm) | 21 (Servo Turret);20 (Swing Arm) | |||

| Max. tool adj. w/o tool | 80/ 150 mm; 75/ 150 mm(Swing Arm) | 80/ 150 mm; 75/150 mm (Swing Arm) | ||||

| Max. tool length | 250 mm; 200 (Swing Arm) | 250 mm; 200 (Swing Arm) | ||||

| Max. tool weight | 3 kg | 3 kg | ||||

| CTC time | 1.6 sec. ; 3.5 sec. (Swing Arm) | 1.6 sec.; 3.5 sec. (Swing Arm) | 1.8 sec.; 3.5 sec. (Swing Arm) | |||

| ISO 230-2 | ||||||

| Positioning accuracy | 0.006 mm | 0.005 mm | ||||

| Repeatability | 0.004 mm | 0.004 mm | ||||

| Coolant System | ||||||

| Coolant tank capacity | 200 L | 200 L | ||||

| Nozzle coolant & flush pump | 70 L/ min 4 bar | 35 L/ min 8 bar;70 L/ min 4 bar | ||||

| Through spindle coolant | 20 bar, 50 bar | 20 bar, 50 bar | ||||

| Lubricant & Cooling | ||||||

| Spindle | Grease | Oil Air | ||||

| Thermal cooling | Option | Spindle Oil Chiller | Spindle oil chiller | |||

| Machine Size | ||||||

| Height | 2,500 mm | 2,500 mm | ||||

| Width x depth | 1,560 x 2,891 mm | 2,100 x 2,891 mm | 1,240 x 2,891 mm 1,560 x 2,891 mm (Swing Arm ) |

1,560 x 2,891 mm | 2,100 x 2,891 mm | |

| Weight | 3,100 kg | 3,300 kg | 3,400 kg | 3,000 kg | 3,100 kg | 3,400 kg |

| Connections | ||||||

| Main power | 55 A/ 220 V/ 3 Phase/ 20 KVA | 55 A/ 220 V/ 3 Phase/ 20 KVA | ||||

| Pneumatic consumption | 6 kg/ cm² | 6 kg/ cm² | ||||

-Two faced contact tools are needed to get better cutting capability.

-Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.

*Maximum output during acceleration.

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.

Related Products

Would you consider customising machines?

Leave us a message. We will present our offer to you.

Contact Us