Multi-Spindle Machining Center

HM4X Series

Machining Capability

Multi-Spindle

Application

-

-

-

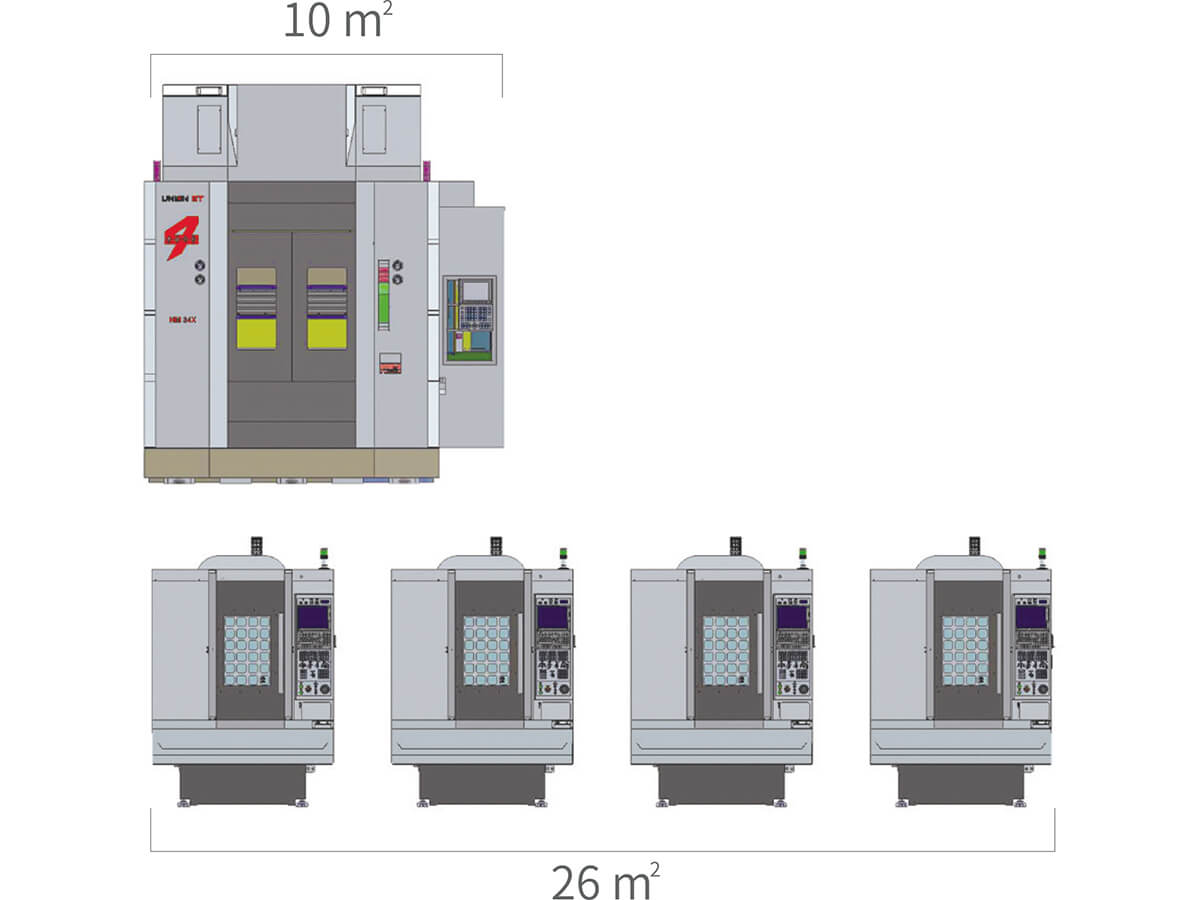

The HM4X horizontal machining center series features high production incorporating with two-spindle or four-spindle and loading/ unloading capability in operation process for high operation efficiency.

- Unique Box-in-Box construction

- DDS- Direct drive spindle

- Max. rigid tapping 8,000 rpm

- X, Y and Z cutting feed rate 20 m/min (788 ipm)

High Productivity

Multiple spindles and four-side trunnion table operation provide higher productivity.

Reliablity and Precision

Central-positioned Z -axis ball screw, dual servo feed systems and pneumatic-hydraulic counter balance system on Y axis for better rigidity and longevity.

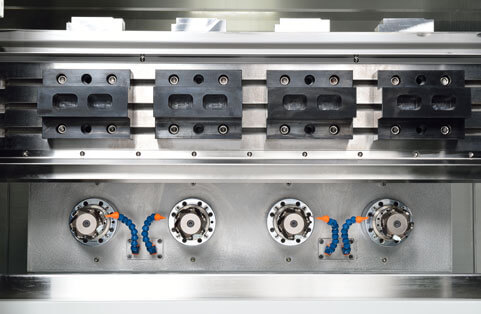

Efficient Loading/ Unloading

Various clamping configurations; clamping of multiple workpiece on each turnnion; up to four set-ups clamping mechanism; up to eight hydraulic lines or air lines for turnnion.

Specification

| ITEM | HM 42X SA | HM 42X | HM 44X |

|---|---|---|---|

| Working Range | |||

| X axis | 460 mm | 460 mm | 235 mm |

| Y axis (tool change) | 500 mm (750 mm) | 500 mm (750 mm) | 500 mm (750 mm) |

| Z axis | 375 mm (Z1, Z2) | 375 mm | 375 mm |

| Spindle distance | 450 mm | 450 mm | 450 mm |

| Worktable | |||

| Trunnion table | 180 x 180 x 1000 mm | 180 x 180 x 1000 mm | 180 x 180 x 1000 mm |

| Load capacity | Max. 250 kg | Max. 250 kg | Max. 250 kg |

| Main Spindle | |||

| Spindle taper | HSK A63/ BBT40 | HSK A63/ BBT40 | HSK A40/ BBT40 |

| Max. spindle speed | 12,000 rpm | 12,000 rpm | 12,000 rpm |

| Spindle bearings | ø60 mm | ø60 mm | ø60 mm |

| Power (S3 15%) | 11 Kw/ 1500 rpm | 11 Kw/ 1500 rpm | 11 Kw/ 1500 rpm |

| Torque (S3 15%) | 70 Nm | 70 Nm | 70 Nm |

| Feed Drive | |||

| Rapid traverse X/ Y/ Z | 48/ 48/ 48 m/ min | 48/ 48/ 48 m/ min | 48/ 48/ 48 m/ min |

| Axis acceleration X/Y/Z | 9.8/ 9.8/ 9.8 m/s² | 9.8/ 9.8/ 9.8 m/s² | 9.8/ 9.8/ 9.8 m/s² |

| Linear guide size | 15,000/ 29,000/ 10,900 N | 15,000/ 29,000/ 10,900 N | 15,000/ 29,000/ 10,900 N |

| ISO 230-2 | |||

| Accuracy positioning | 0.01 mm | 0.01 mm | 0.01 mm |

| Repeatability | 0.005 mm | 0.005 mm | 0.005 mm |

| Automatic Tool Changer | |||

| Tool change system | Pick-Up | Pick-Up | Pick-Up |

| Capacity | 2 x 32 (2 x 44/ 2 x 60) | 2 x 32 (2 x 44/ 2 x 60) | 4 x 16 (4 x 22/ 4 x 30) |

| Max. tool diameter | ø80 mm/ 125 mm | ø80 mm/ 125 mm | ø80 mm/ 125 mm |

| Max. tool length | 275 mm | 275 mm | 275 mm |

| Max. tool weight | 6 kg | 6 kg | 6 kg |

| Tool change time | 3.5 sec. | 3.5 sec. | 3.5 sec. |

| Machine Size | |||

| Total weight | 12,700 kg | 12,500 kg | 13,000 kg |

| Machine size | 3.1 m x 3.3 m x 3.4 m | 3.1 m x 3.3 m x 3.4 m | 3.1 m x 3.3 m x 3.4 m |

| Controller | |||

| Fanuc | 0i MF | 0i MF | 31 i |

-Two faced contact tools are needed to get better cutting capability.

-Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.

*¹Fanuc system spindle & servo motors adopt alpha series motors.

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.

Related Products

Would you consider customising machines?

Leave us a message. We will present our offer to you.

Contact Us