Multi Spindle Machine, 5 Axis Machine & CNC Vertical Machining Center for High-Precision Manufacturing

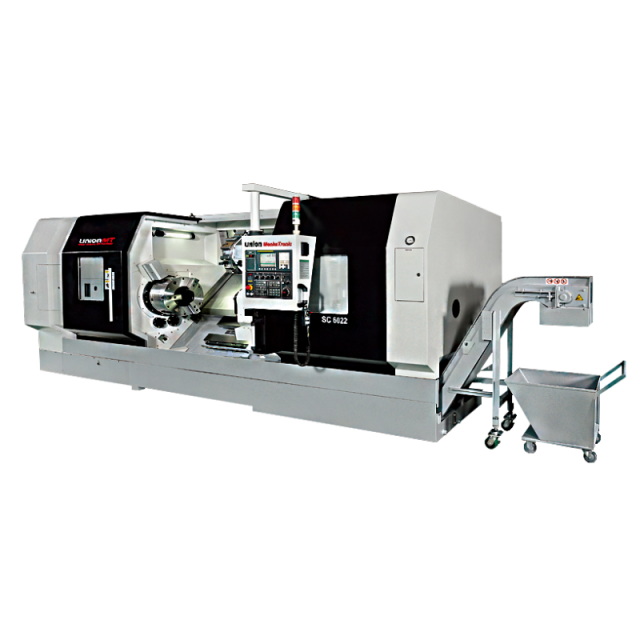

Union MT offers a wide range of high-efficiency precision machining solutions, including Multi Spindle CNC Machine, 5 Axis Machine, Vertical CNC Machine, CNC Horizontal Turning Center, Heavy Duty CNC Lathe Machine and Ultra Precision Products.

These technologies are widely applied in industries such as aerospace, automotive, electronics, small to medium-sized components, and medical devices. Whether your needs are for high-precision machining or large-scale production, we combine advanced technology with optimized design to deliver the best solutions for you.