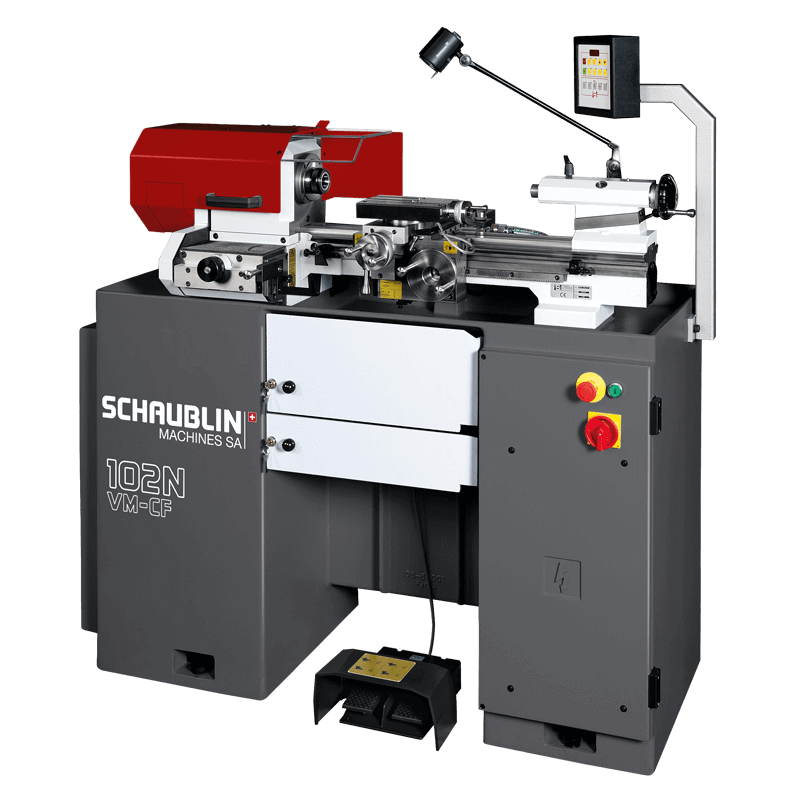

Ultra Precision Products

102N-VM-CF

Conventional Turning

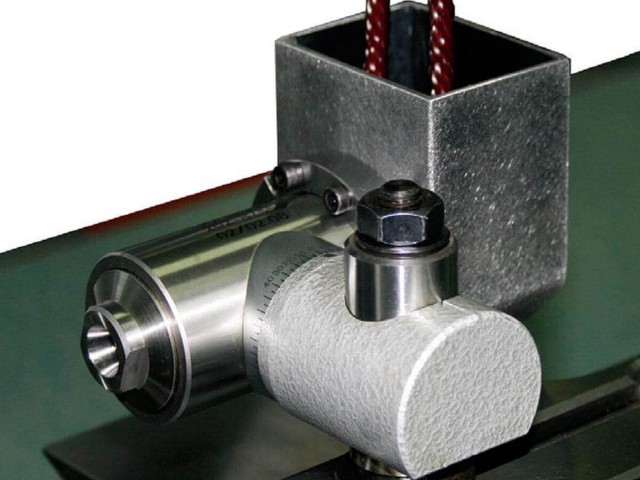

A proven machine which is highly renowned for its advantages and manifold possibilities of use. This machine consists of more than 800 mechanical parts and is equipped with a lead screw. It is ideal for machining threads and other special workpiece features. Equipped with W25 collet. Drive CF for milling or grinding attachements, including:

- Adjustable and swivelling belt-tensioning attachment

- Drive device complete - motor 0.44 kW

- Speed variation by frequency converter

- Belt Ø 6 x 2,500 mm

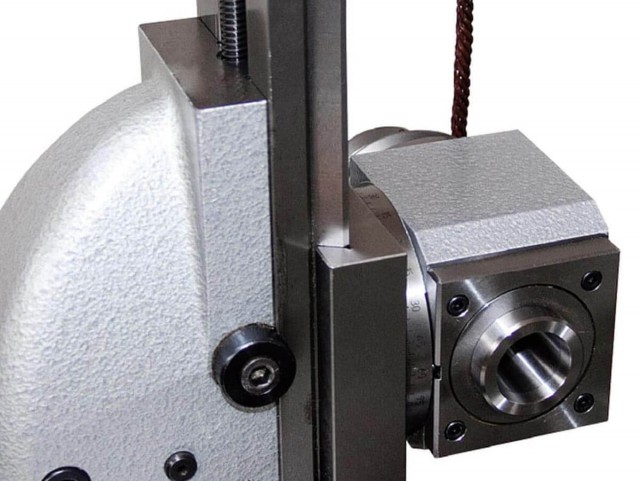

Pressure Regulator

Pressure regulator for cooling of grinding and milling attachments

Control Panel Conception

The control panel conception enables the user toprogram the spindle, the milling/grinding attachment (if mounted) and miscellaneous auxiliary functions.

Frequency Converter

Frequency converter for the grinding and milling attachment

| 102 N-VM-CF | Bench | Cast iron | ||

|---|---|---|---|---|

| Machining Capacity | ||||

| Max. permissible swing over bed | 200 mm | 200 mm | ||

| Max. permissible swing over carriage | 120 mm | 120 mm | ||

| Center height over bed | 102 mm | 102 mm | ||

| Center height over carriage | 20 mm | 20 mm | ||

| Maximum distance between centres | 470 mm | 470 mm | ||

| Principal spindle; by AC motor drive | ||||

| Power continuous | 1.5 kW | 2.0 Kw | ||

| Headstock( W20/ W25 ) | ||||

| Spindle for SCHAUBLIN collets | W20/ W25 | W20/ W25 | ||

| Spindle speed | 10-6000 min¯¹ | 10-6000 min¯¹ | ||

| Spindle throughbore (without drawbar) | 20 mm / 25 mm | 20 mm / 25 mm | ||

| Max. throughbore with collet W20/ W25 | 14.5 / 19 mm | 14.5 / 19 mm | ||

| Cross slide | ||||

| Manual travel of the slide on the bed | 442 mm | 442 mm | ||

| Transverse stroke, X axis | 100 mm | 100 mm | ||

| Resolution, X axis (radius) | 0.001 | 0.001 | ||

| Trapezoidal thread screw, dia. x pitch | ø9.0 / 2.0 mm | ø9.0 / 2.0 mm | ||

| Longitudinal stroke, Z axis | 90mm | 90mm | ||

| Resolution, Z axis | 0.001 | 0.001 | ||

| Trapezoidal thread screw, dia. x pitch | ø9.0 / 2.0 mm | ø9.0 / 2.0 mm | ||

| Pneumatic chucking (Option) | ||||

| Maximum spindle speed | 6,000 min-1 | 6,000 min-1 | ||

| Adjustable axial clamping force, at 5 bars | 500 daN | 500 daN | ||

| Tooling system: Linear | ||||

| Max. tool size (MULTIFIX system) | 10 * 10 mm | 10 * 10 mm | ||

| Max. tool size (TRIPAN system) | 10 * 10 mm | 10 * 10 mm | ||

| Bar holder dia. (Multifi x system) | 20 mm | 20 mm | ||

| Bar holder dia. (Tripan system) | 12 mm | 12 mm | ||

| Screw operated tailstock | ||||

| Internal taper of the sleeve | W20/W25 | W20/W25 | ||

| Spindle OD | 40 mm | 40 mm | ||

| Spindle stroke | 100 mm | 100 mm | ||

| Lever-operated tailstock (option) | ||||

| Internal taper of the sleeve | MORSE 2 | MORSE 2 | ||

| Spindle OD | 30 mm | 30 mm | ||

| Spindle stroke | 80 mm | 80 mm | ||

| Fixed steady (optional) | ||||

| Capacity of stationary steady, ø | 70 mm | 70 mm | ||

| Dimensions and weight | ||||

| Approximate net weight of the machine | 360 kg | 570 kg | ||

| Load floor | 263 kg/m² | 1,541 kg/m² | ||

| Overall dimensions in mm length x depth x height | 2,000 x 800 x 1,370 mm | 1,410 x 650 x 1,400 mm | ||

-The 102 High Precision Lathes are in conformity with the European Community safety regulations. In view of the constant improvements made to our products, technical data illustrations, dimensions, and weights appearing in this catalogue are subject to change without notice