Flat Bed Lathe

TC Series

Machining Capability :

CNC Big Bore

The precision CNC heavy duty lathe- TC 510/ 610/ 810 series- enables Union MT machines to present a solution for high precision production as well as small batch or prototype high precision machining.

- Heavy duty cutting

- Efficient chip removal

- Smart and complete machine inspection

- Big bore and large size parts applications

Application Industry

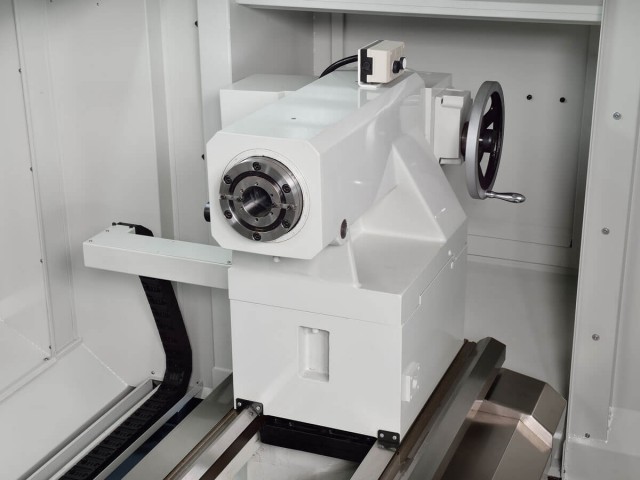

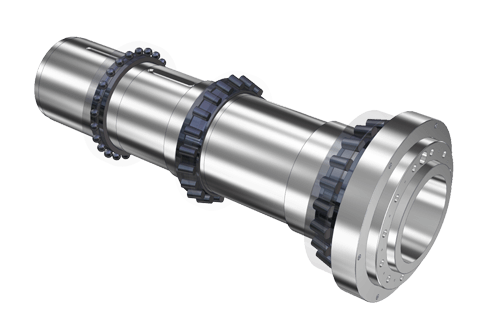

Large Spindle Bore

Three sets of precision taper roller spindle bearings ensure rigidity and concerntricity.

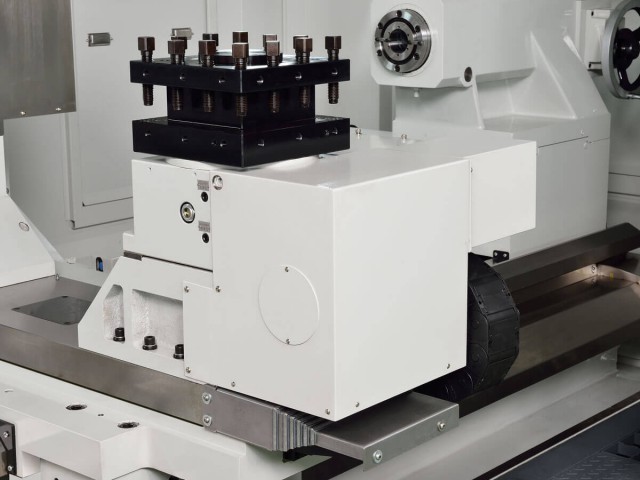

Wide Carriage and Saddle

Wide carriage and cross slide design increase the contact area for greater cutting stiffness and rigidity.

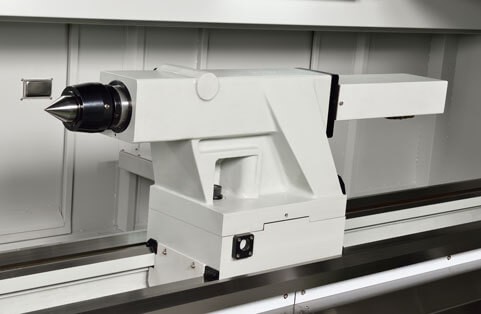

Robust Tailstock

Robust tailstock structure with MT#6 or MT#7 quill- provides heavy duty cutting and drilling capability.

Specification

| TC 510 | TC 610 | TC 810 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ITEM | 860 | 960 | 1060 | 1170 | 1270 | 1370 | 1400 | 1600 | 1800 | |||||

| Capacity | ||||||||||||||

| Center height | 430 mm (16.93") |

480 mm (18.90") |

530 mm (20.87") |

585 mm (23.03") |

635 mm (25.00") |

685 mm (26.98") |

700 mm (27.56") |

800 mm (31.50") |

900 mm (35.43") |

|||||

| Swing over bed | 860 mm (33.86") |

960 mm (37.80") |

1,060 mm (41.73") |

1,170 mm (46.06") |

1,270 mm (50.00") |

1,370 mm (53.94") |

1,400 mm (49.12") |

1,600 mm (62.99") |

1,800 mm (70.87") |

|||||

| Width of bed | 510 mm (20.08") | 610 mm (24.02") | 810 mm (31.89") | |||||||||||

| Bed way | 3V Guideways | 3V Guideways + 1 support | 3V Guideways + 1 support | |||||||||||

| Spindle | ||||||||||||||

| Spindle bore | 105 mm | 153 mm | 230 mm | 318 mm | 153 mm | 230 mm | 318 mm | 380 mm | 410 mm | 153 mm | 230 mm | 318 mm | 380 mm | 410 mm |

| Spindle nose | A2-8 | A2-11 | A2-15 | A2-20 | A2-11 | A2-15 | A2-20 | A2-20 | A2-28 | A2-11 | A2-15 | A2-20 | A2-20 | A2-28 |

| Spindle speeds | 1,200 rpm | 1,000 rpm | 700 rpm | 500 rpm | 1,000 rpm | 700 rpm | 500 rpm | 450 rpm | 300 rpm | 1,000 rpm | 700 rpm | 500 rpm | 450 rpm | 300 rpm |

| Feed Mechanism | ||||||||||||||

| X axis travel | 430 mm (16.93") |

480 mm (18.90") |

530 mm (20.87") |

585 mm (23.03") |

635 mm (25.00") |

685 mm (26.97") |

700 mm (27.56") |

800 mm (31.50") |

900 mm (35.43") |

|||||

| Z axis travel | 1.2/ 1.7/ 2.7/ 3.7/ 4.7/ 5.7/ 6.7/ 7.7/ 8.7/ 9.7/ 10.7/ 11.7 m *travel changed by chuck, turret or tailstock |

1.7/ 2.7/ 3.7/ 4.7/ 5.7/ 6.7/ 7.7/ 8.7/ 9.7/ 10.7/ 11.7 m *travel changed by chuck, turret or tailstock |

1.7/ 2.7/ 3.7/ 4.7/ 5.7/ 6.7/ 7.7/ 8.7/ 9.7/ 10.7/ 11.7 m *travel changed by chuck, turret or tailstock |

|||||||||||

| Turret | ||||||||||||||

| Tool post | E4 Electronic | V8 Hydraulic | V8 Hydraulic | |||||||||||

| Tailstock | ||||||||||||||

| Quill taper | MT#6 | MT#6 (MT#7 Option) | MT#6 (MT#7 Option) | |||||||||||

| Quill travel | 300 mm (11.81'') | 300 mm (11.81'') | 300 mm (11.81'') | |||||||||||

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.

Related Products