Vertical Machining Center

MV1000

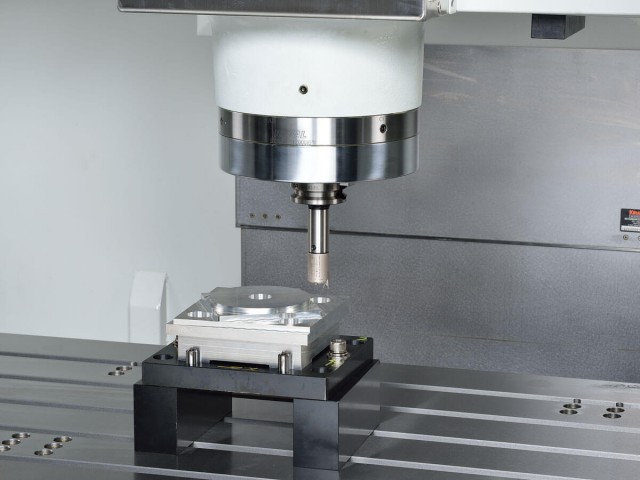

Mold

The MV1000 Vertical Machining Center is a cutting-edge machine that offers the largest working range, exceptional accuracy, and longevity. The mating surfaces on every machine are meticulously hand-scraped by our experienced craftsmen to insure the utmost precision, efficiency, and long-term accuracy.

Vertical Mills have extensive and diverse applications in various industries such as automotive, precision mold manufacturing, and consumer electronics.

- Acceleration rates of 1 G

- Machine stiffness > 2.5 kgf/um

- 48m/min rapids

- Spindle technology up to 15,000 rpm

High Productivity

Standard swing arm ATC 24 tools with max. tool diameter 90 mm/ 180 mm, with/ without adjacent tool feature big surface milling and enable better surface roughness without surface gap.

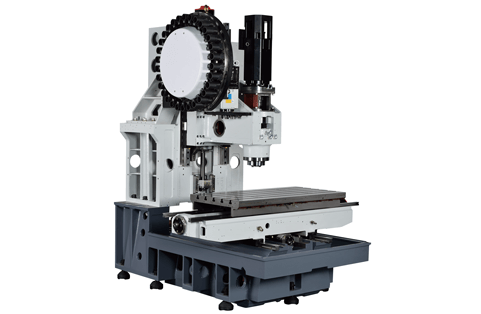

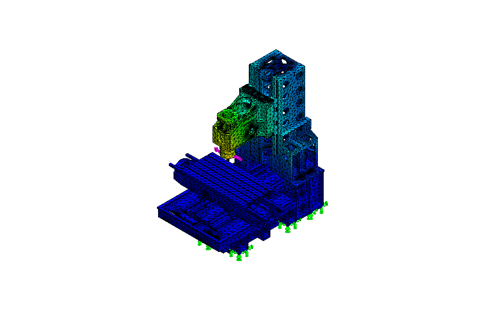

Robust Machine Structure

Wider column span, heavy duty and high precision roller linear guides of 35/ 45/ 45 mm on X/ Y/ Z and large 45 mm diameter pretensioned ball screws ensure transmission rigidity and machining stability.

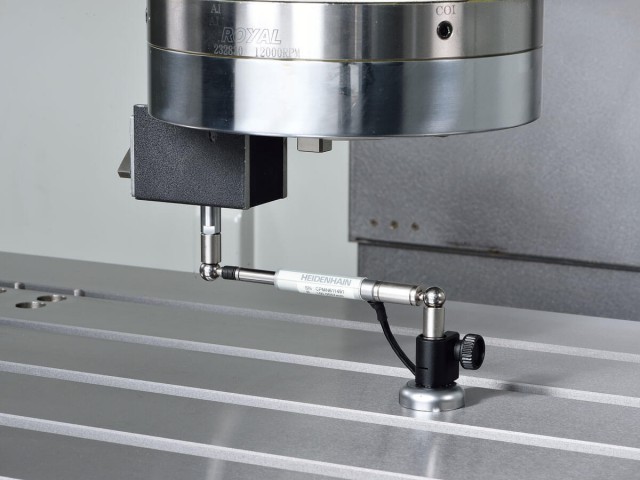

Reliable DDS- Direct Drive Spindle

The design of short type spindle nose and 4 P4 angular contact ceramic bearings can fix and support the bearings into spindle housing and headstock as to increase cutting stiffness.

| P Specification | M Specification | |||||

|---|---|---|---|---|---|---|

| ITEM | 10 P | 12 P | 15 P | 12 M | 15 M | 24 M |

| Working Range | ||||||

| Travel X/Y/Z | 1,020/ 610/ 610 mm | 1,020/ 610/ 610 mm | ||||

| Table size | 1,200 x 600 mm | 1,200 x 600 mm | ||||

| Table load capacity | 900 kg | 900 kg | ||||

| Main Spindle | ||||||

| Max. spindle speed | 10,000 rpm | 12,000 rpm | 15,000 rpm | 12,000 rpm | 15,000 rpm | 24,000 rpm |

| Feed Drive | ||||||

| Rapid travel X/Y/Z | 36/ 36/ 36 m/ min | 48/ 48/ 48 m/ min | ||||

-Two faced contact tools are needed to get better cutting capability.

-Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.

*¹Fanuc system spindle & servo motors adopt alpha series motors.

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.