Vertical Machining Center

MV300 / 500 / 700#40

Drilling and Tapping

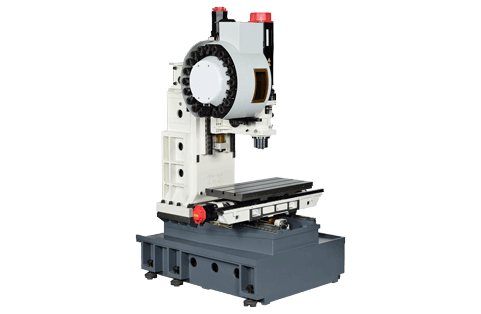

Compact MV 300/500/ 700 high performance series features the largest working range with compact footprint design. The surperior accuracy and reliability from excellent scrape skill are suitable for high precision milling machining.

- High acceleration rates 1.5 G

- Machine stiffness > 2.5 kgf/um

- 60 m/min rapids

- Spindle technology up to 15,000-40,000 rpm

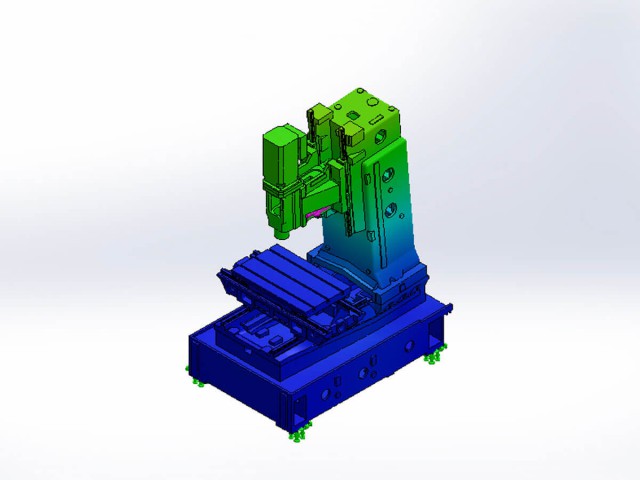

Robust Machine Structure

Symmetrical headstock and enhanced ribs design to reduce vibrations, termal displacement and cutting stability.

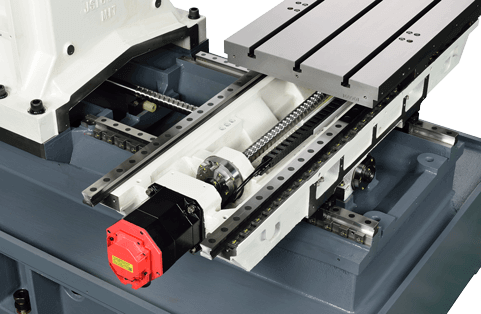

Soild Transmission Structure

X, Y and Z axes feed mechanism are direct driven to assure the transmission efficiency and high precision. C1 ball screw provides superior positioning accuracy without backlash errors.

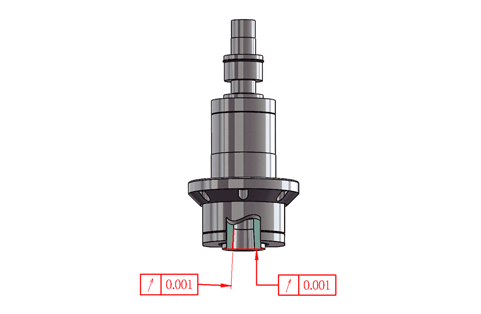

Reliable DDS- Direct Drive Spindle

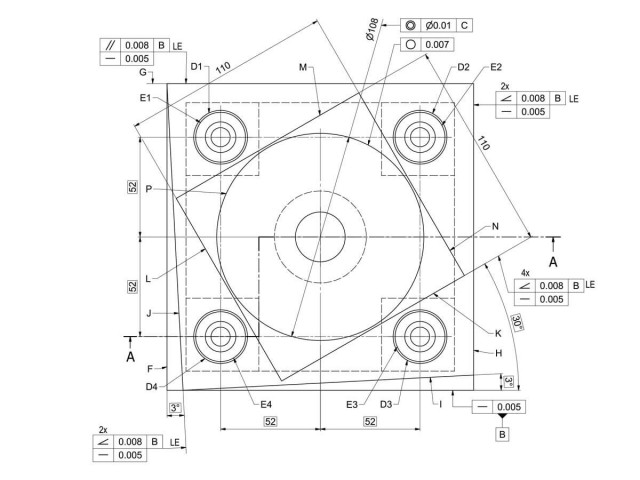

Spindle nose run out 0.001 mm and 0.006 mm at measuing length 250 mm of test mandrel.

| ITEM | 300P | 500P | 700P | |||

|---|---|---|---|---|---|---|

| Working Range | ||||||

| Travel X/Y/Z | 300 x 400 x 450 mm | 500 x 400 x 450 mm | 700 x 400 x 450 mm | |||

| Table size | 650 x 410 mm | 750 x 410 mm | 850 x 410 mm | |||

| Table load capacity | 250 kg | 280 kg | 300 kg | |||

| Main Spindle | ||||||

| Max. spindle speed | 10,000 rpm | 12,000 rpm | 15,000 rpm | |||

| Automatic Tool Changer | ||||||

| Magazine pots | 20 | |||||

| Max. tool adj. w/o tool | 75/ 150 mm | |||||

| Max. tool length | 200 mm | |||||

| Max. tool weight | 6 kg | |||||

| CTC time | 3.5 sec. | |||||

| ISO 230-2 | ||||||

| Positioning/ Repeatability | 0.006/ 0.004 mm | |||||

| Coolant System | ||||||

| Coolant tank capacity | 200L | |||||

| Nozzle coolant & flush pump | 70L/ min 4 bar | |||||

| Lubricantion | ||||||

| Spindle | Grease | |||||

| Machine Size | ||||||

| Height | 2,500 mm | |||||

| Width x depth | 1,560 x 2,891 mm | 1,560 x 2,891 mm | 2,100 x 2,891 mm | |||

| Weight | 3,000 kg | 3,100 kg | 3,400 kg | |||

-Two faced contact tools are needed to get better cutting capability.

-Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.