Ultra Precision Products

302

Turning and Grinding Center

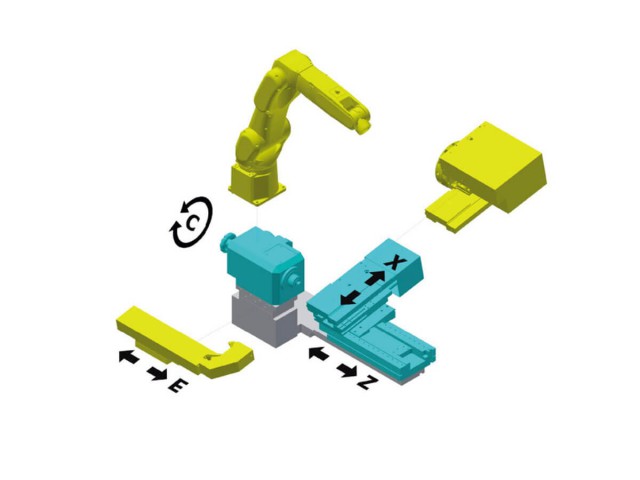

The 302 unit's compact size and flexbility guarantee economic small and large scale production runs! The 302 unit combines modernity and traditioin, with the Fanuc 0i TF control system for automated mass production.

- Space saving design

- Max. use of C axis is 20%

- High precision production lathe with FANUC digital control

- Machine fitted with coolant supply system and 55 l. tank

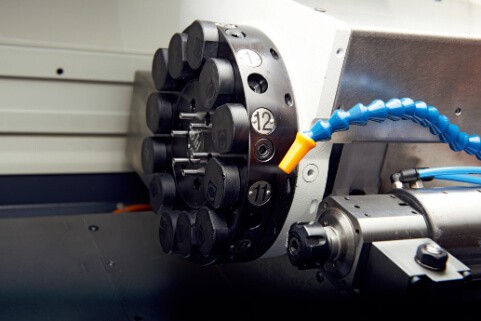

SAUTER VDI 16

The compact precision revolver unit has 12 stations SAUTER VDI 16. They all have coolant supply from the centre and 6 driven positions.

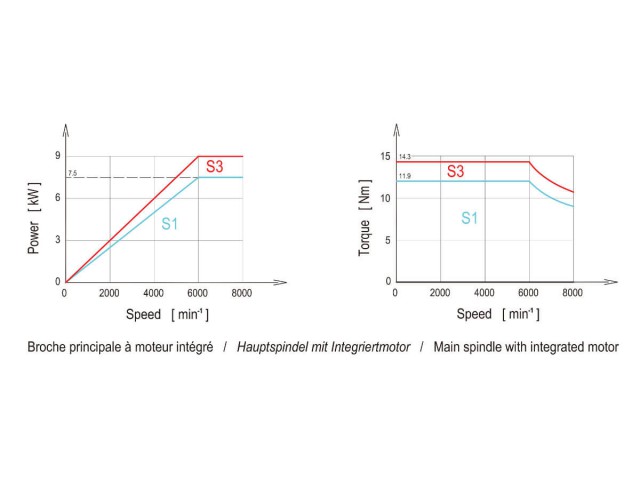

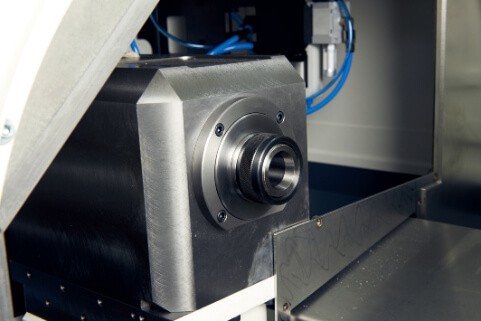

High Precision Spindle

The high precision spindle has an integrated motor. Available on the W20 and W25 versions. Pneumatic clamping is possible as an option.

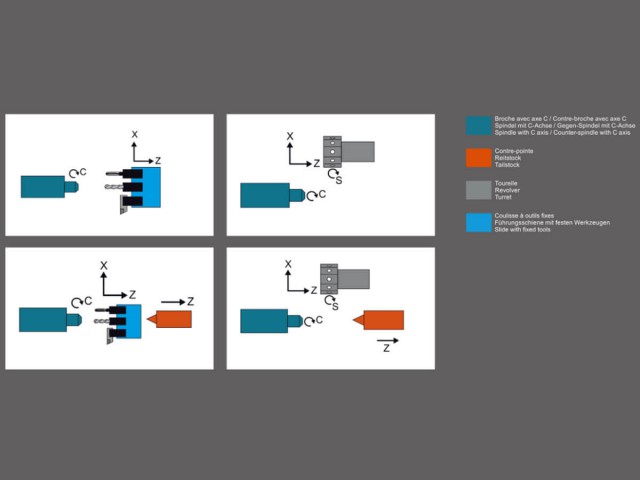

Working Area

Large access hatch for simple and easy access to the working area. Robotic part loading available as an option.

| 302 | |||

|---|---|---|---|

| Machining Capacity | |||

| Height of centers over carriage | 200 mm | ||

| Maximum turning diameter | X: 460 mm/ Y: 610 mm (+305 ~ ‐305)/ Z: 510 mm | ||

| Turning length with collets W20/W25 | 200 mm | ||

| Distance between centers | 220 mm | ||

| Headstock | |||

| Spindle for “SCHAUBLIN” collets | W20 / W25 | ||

| Spindle speed | 50 - 8000 min¯¹ | ||

| Power continuous / intermittent | 7.5/ 9 kW | ||

| Programmable increment | 0.001° | ||

| Spindle throughbore with clip (without drawbar) | 17mm / 21mm | ||

| Maximum throughbore with collet W20/W25 | W20:14.5 mm / W25:19 mm | ||

| Pneumatic clamping (option) | |||

| Adjustable axial clamping force, at 5 bars | 500 daN | ||

| Maximum spindle speed | 140 mm | ||

| Carriage | |||

| Transverse stroke, X-axis | 6,000 min¯¹ | ||

| Resolution, X-axis (on radius) | 0.00005 mm | ||

| Ball screw, Ø x pitch | 20 x 4 mm | ||

| Longitudinal stroke, Z-axis | 240 mm | ||

| Resolution, Z-axis | 0.0001 mm | ||

| Ball screw, Ø x pitch | 20 x 4 mm | ||

| Rapid feed, X- and Z-axis | 16 m/ min | ||

| Tooling system: Linear | |||

| Number of radial toolholder (according to Ø of the piece) | 2 | ||

| Number of frontal toolholder (according to Ø of the piece) | 2->5 | ||

| Maximum tool size (MULTIFIX/ SMSA) | 12 x 12 mm | ||

| Milling and Grinding attachment (options) | Yes | ||

| Clamping tools for collets | ESX 20 / ESX 9 | ||

| Tailstock operated with screw (option) | |||

| Spindle taper | MORSE 2 | ||

| Stroke | 235 mm | ||

| Possibility of the motorized tailstock | Yes | ||

| Revolver (option) | |||

| Number of tool station | 12 | ||

| Number of rotating tool station | 6 | ||

| Standardized fixing of toolholders | SAUTER VDI 16 | ||

| Maximal speed | 6000 min¯¹ | ||

| Power continuous/ intermittent | 1/ 1.3 Kw | ||

| Torque continuous/ intermittent | 3/ 7.5 Nn | ||

| Coolant supply (option) | |||

| Tank capacity | 60 l. | ||

| Pump capacity | 40 l/min | ||

| Pump pressure | 1.5 bars | ||

| Dimensions and weight | |||

| Approximate net weight of the machine | 1,100kg | ||

| Overall dimensions in mm L x D x H | 1,795 x 969 x 1,485 | ||

The 302 High Precision Lathes are in conformity with the European Community safety regulations (CE). In view of the constant improvements made to our products, technical data, illustrations, dimensions and weights appearing in this catalogue are subject to change without notice.