Ultra Precision Products

202TG

Turning and Grinding Center

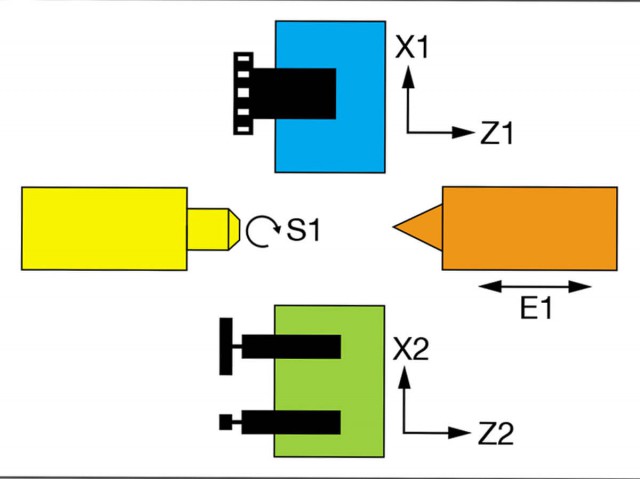

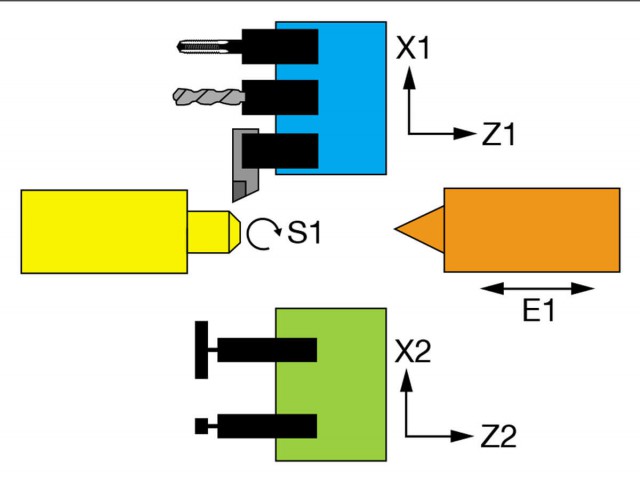

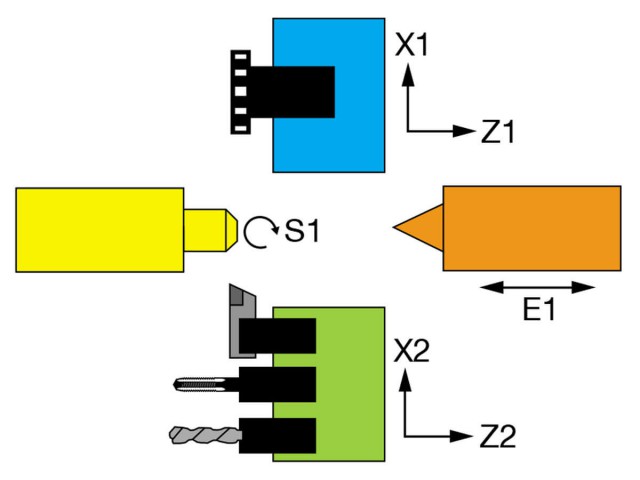

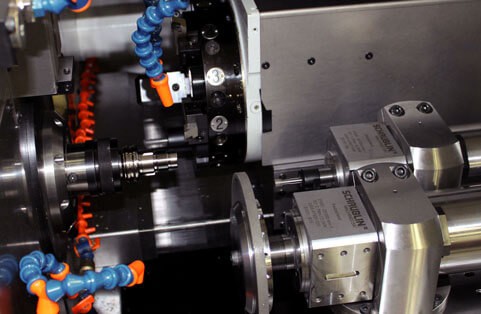

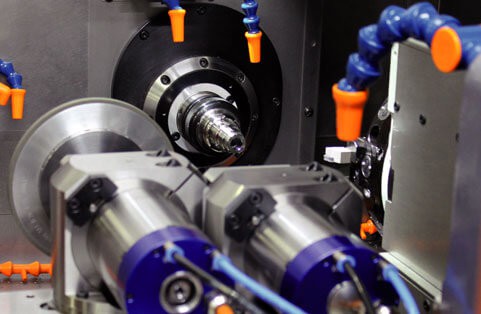

The 202TG range of modular machines with configurations that offers both solutions in budget and versatility for the exacting needs of the end user in targeting high precision components that require turning, hard turning, grinding, internal and external milling, cross drilling and tapping. The 202 TG enables Schaublin Machines to present a solution for either high production environments as well as small batch or prototype high precision machining.

- Up to 8 simultaneous axis

- Heindenhain glass scales on all linear axis

- 12 station turret VDI 16-6 driven tools 6,000 rpm

- Minimum floor space compact design

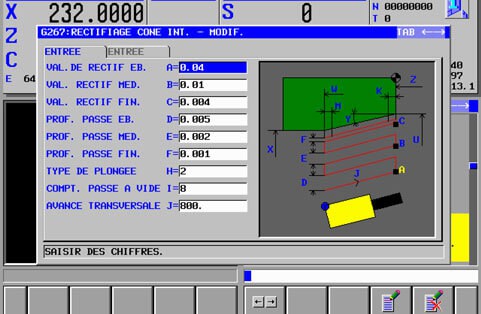

Programming Assistant (Option)

Special CNC page for the fix parameter and programming cycles. Also, different cycles will be made according to the customer application request.

High Speed Spindle Technology

Internal grinding spindles up to 60,000 rpm External grinding spindles up to 25,000 rpm

Hrc 65

Suitable for hard turning 65 Hrc Generating a surface of Ra= 0.1

| ITEM | 202TG |

|---|---|

| Machining Capacity | |

| Maximum turning diameter | 80 mm |

| Maximum turning length: W25 | 150 mm |

| Headstock W25 | |

| Spindle for “Schaublin” collets | W25 |

| Spindle speed | 50 - 7000 min-1 |

| Power continuous / intermittent | 5/6 Kw |

| Torque continuous / intermittent | 26.1 / 35.1 Nm |

| Maximum throughbore with collet | 19 mm |

| C Axis | YES |

| Carriage | |

| Stroke X1, X2 / Z1, Z2 axis | 150, 150 / 300, 300 mm |

| Resolution, X-axis (on radius) | 0.0005 mm |

| Feed rate | |

| Working feeds, X & Z axis | 8 / 8 m/min |

| Tailstock (Option) | |

| Spindle taper | MORSE 2 |

| Stroke | 660 mm |

| Tooling system: Revolver (Option) | VDI 16 |

| Maximal speed | 6,000 RPM |

| Power continuous / intermittent | 1 / 1 Kw |

| Torque continuous / intermittent | 3 / 7 Nm |

| Grinding spindle (Option) | |

| Maximal speed | 25,000 / 60,000 RPM |

| Power continuous / intermittent | 7-9 / 6-8 kW |

| Torque continuous / intermittent | 2.7-3.5 / 1-1.3 Nm |

The 202 TG High Precision Lathe is in conformity with the European Community safety regulations. In view of the constant improvements made to our products, technical data illustrations, dimensions, and weights appearing in this catalogue are subject to change without notice.