CNC Horizontal Turning Center

SL Series

Linear Guide

CNC Horizontal Turning Centers SL series equipped with rich optional such as live tooling turret, Y-axis, sub-spindle and loading/ unloading can work on turning, milling, drilling system tasks at the same time as to increase machining capacity on your demand.

- 45° slant-bed structure

- Fin type headstock

- Enhanced one piece base and bed

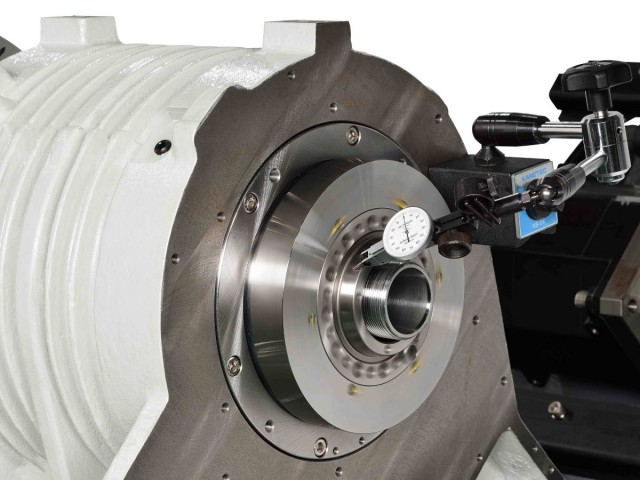

- Reliable and superior accuracy SKF spindle

High Performance

Enhanced solid rigidity base and bed, the one piece construction without hollow cavity provides higher rigidity and suitable to high precision and hard turning.

Robust Machine Structure

Symmetrical fin type headstock and enhanced ribs design to reduce vibrations and thermal displacement. Spindle chiller for thermal cooling control is optional to increase precision level and stability control.

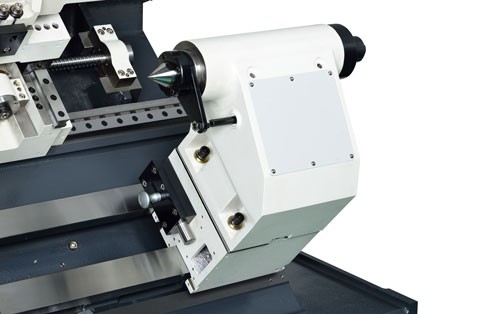

Rigid Tailstock and Turret

Programmable tailstock features robust box way for rigidity; the quill travel design for better long shaft machining accuracy.

| ITEM | SL 1500 | SL 2000 | SL 2000B | SL 2500 | SL 3000 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Working Range | ||||||||||

| Spindle Nose | A2-5 | A2-6 | A2-6 | A2-8 | A2-8 | |||||

| Swing Over Bed | 460 mm | 535 mm | 610 mm | 690 mm | 690 mm | |||||

| Max. Turning Diameter | 285 mm | 360 mm | 410 mm | 500 mm | 500 mm | |||||

| Max. Turning Length | 360 mm | 610 mm | 360 mm | 610 mm | 610 mm | 1,020 mm | 610 mm | 1,020 mm | 1,020 mm | 1,500 mm |

| Hole Through Draw Tube | 45 mm | 52 mm | 66 mm | 78 mm | 91 mm | |||||

| Main Spindle | ||||||||||

| Jaw Chuck Size | 6''/ 169 mm | 8''/ 210 mm | 8''/ 210 mm | 10''/ 254 mm | 12''/ 304 mm | |||||

| Spindle Speed | 6,000 mm | 5,000 mm | 4,200 rpm | 3,500 rpm | 2,500 rpm | |||||

| X/ Z Axis | ||||||||||

| X Axis Travel | 163 mm | 200 mm | 230 mm | 275 mm | 275 mm | |||||

| Z Axis Travel | 360 mm | 610 mm | 360 mm | 610 mm | 610 mm | 1,020 mm | 610 mm | 1,020 mm | 1,020 mm | 1,500 mm |

| Turret | ||||||||||

| Stations | 12 | 12 | 12 | 12 | 12 | |||||

-Two faced contact tools are needed to get better cutting capability.

-Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.

*¹Fanuc system spindle & servo motors adopt alpha series motors.

*Please be aware of the continuous performance improving policy, UnionMT reserves the rights to change product specifications, data, options, appearances and etc. without notice.