Ultra Precision Products

CUBE 350

Machining Capability :

Centerless Grinding

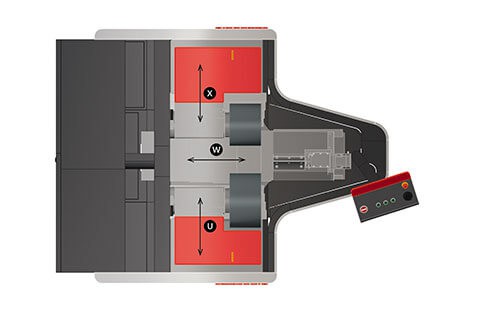

The patented 3-axes concept significantly simplifies the entire system for maximized reliability and uptime. The patented movable workrest axis (W-Axis) allows for additional grinding processes and even complex profiles can be ground. The loading and unloading of the workpieces is always outside of the grinding zone, allowing simplified and safe automation or safe manual loading.

- Machine concept – less parts, more reliability

- Set up process – digitally stored setting data to recall

- Operation process – anyone can reproduce identical results

- Grinding process – consistency by mastering thermal growth

Application Industry

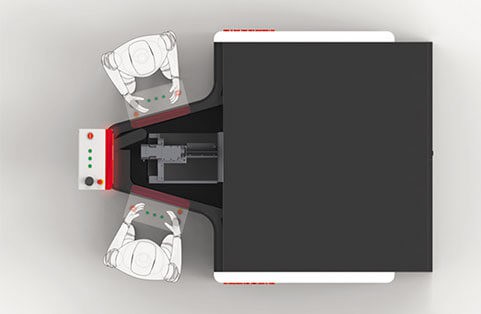

Safe Loading/Unloading

Loading and unloading of the workpiece outside of the grind zone results in higher reliability. The automation is not within the dirty grinding zone.

Ergonomie, Function and Design

Ergonomic operations for left-and-right-handed users (patent pending) Simple and convenient handling (software TSCHUDIN ) Best accessibility and maintenance

TSCHUDIN PATENT

U: Grinding Wheel W: Workset Blade X: Regulating Wheel

Specification

| Process | TSCHUDIN Cube 350 |

|---|---|

| Through feed grinding rinding area Ø |

0.1-20 mm |

| Plunge grinding Grinding area Ø |

0.1-20 mm |

| Grinding wheel width Grinding length Plunge grinding |

150 mm (optiona 205 mm) |

| Grinding wheels Ø | 350 mm |

| Bore diameter | 203.2 mm |

| Regulating wheels Ø | 275 mm |

| Bore diameter | 175 mm |

| Drive power grinding spindle |

7.5 / 12 kW |

| Peripheral speed grinding wheel (V-constant) |

max. 63 m/s |

| Speed regulating wheel (infinitely variable) |

5-1,000/min |

| CNC control | Fanuc 0i |

| Resolution | 0.1 μ |

| Dimensions L x T x H | 2,558 x 1,735 x 1,320 mm |

| Weight | 4 t |