Ultra Precision Products

180-CCN

Hard Turning

CCN

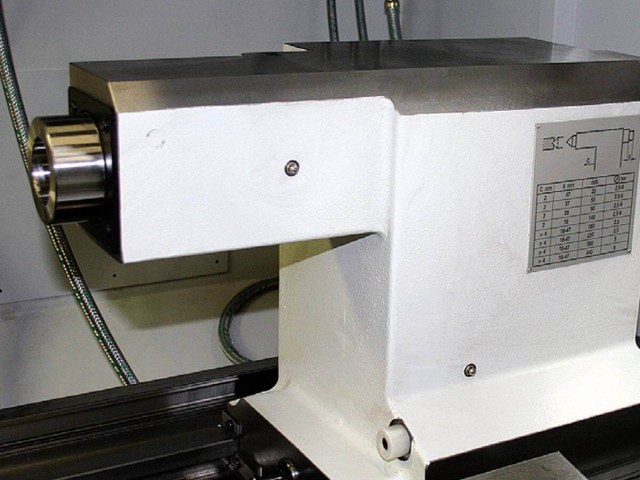

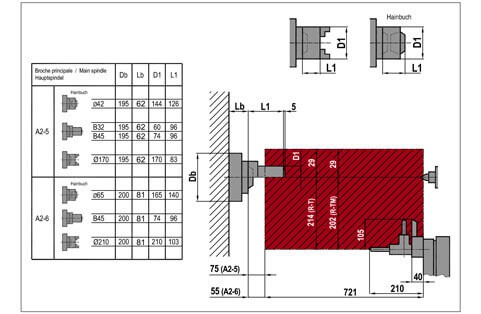

High-precision lathes with numerical control by Fanuc. R-T version for turning with a turret with 8 stationary tools. A2-5 spindle nose for Schaublin collets B32 / B45. This machine is used for turning medium-sized and large workpieces. This lathe has been designed to produce prototypes and workpieces in small to medium-sized lots. It is ideal for hard turning.

- Flexibility

- Longevity

- High precision

- Specialities

CCN-Turning as Simple and Flexible as Conventional Turning!

The CCN (conventional control numerical) lathe combines the advantaged a numerical control and the simplicity of a conventional lathe.

Working Areas

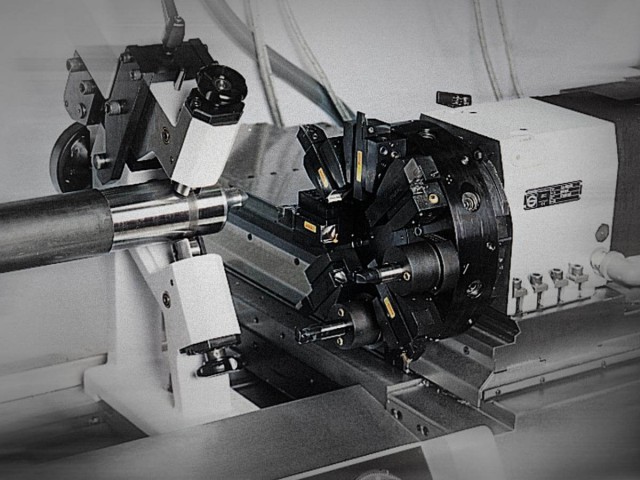

Rotating turret with fixed and driven tools

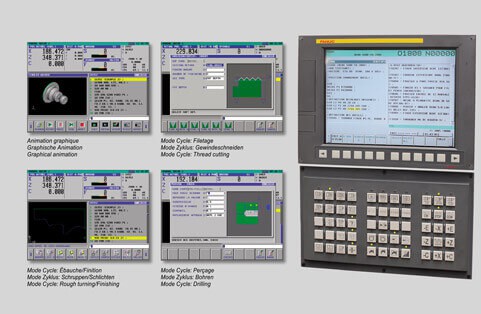

Fanuc 0i-TD Control

Some mode cycle, including graphical animation, thread cutting, rough turning/ finishing, and drilling, shown on the Fanuc screen.

| ITEM | R-T / A2-5 | R-T / A2-6 | R-TM / A2-5 | R-TM / A2-6 |

|---|---|---|---|---|

| Machining Capacity | ||||

| Maximum turning diameter | 330 mm | 330 mm | 270 mm | 270 mm |

| Maximum swing over carriage | 160 mm | 160 mm | 160 mm | 160 mm |

| Hegiht of centers over carriage | 83 mm | 83 mm | 83 mm | 83 mm |

| Maximum turning length | 655 mm | 635 mm | 655 mm | 635 mm |

| Headstock | A2-5 | A2-6 | A2-5 | A2-6 |

| Spindle for SCHAUBLIN collets | B32 / B45 | B45 | B32 / B45 | B45 |

| Spindle speed | 50 - 4000 min¯¹ | 50 - 4000 min¯¹ | 50 - 4000 min¯¹ | 50 - 4000 min¯¹ |

| AC motor drive:Power continuous/ intermittent | 15 kW / 18.5 kW | 15 kW / 18.5 kW | 15 kW / 18.5 kW | 15 kW / 18.5 kW |

| Spindle throughbore (without drawbar) | 51 mm | 68 mm | 51 mm | 68 mm |

| Spindle throughbore with collet | 24 / 36 mm | 36 mm | 24 / 36 mm | 36 mm |

| Maximum throughbore with automatic chuck | 43.6 mm | 61 mm | 43.6 mm | 61 mm |

| Pneumatic clamping | ||||

| Adjustable axial clamping force, at 5 bars | 2700 daN | 3400 daN | 2700 daN | 3400 daN |

| C axis | ||||

| Programmable increment | - | - | 0.001° | 0.001° |

| Carriage | ||||

| Maximum transverse stroke, X- axis | 243 | 243 | 231 | 231 |

| Resolution, X axis (on-radius) | 0.0005 mm | 0.0005 mm | 0.0005 mm | 0.0005 mm |

| AC motor drive: Continuous/ intermittent torque | 4 / 14 Nm | 4 / 14 Nm | 4 / 14 Nm | 4 / 14 Nm |

| Manual moving of carriage on bed | 721 mm | 721 mm | 721 mm | 721 mm |

| Resolution, Z- axis | 0.001 mm | 0.001 mm | 0.001 mm | 0.001 mm |

| AC motor drive: Continuous/ intermittent torque | 8 / 29 Nm | 8 / 29 Nm | 8 / 29 Nm | 8 / 29 Nm |

| Feeds | ||||

| Working feeds, X- and Z-axis, stepless | 0-5 m/min | 0-5 m/min | 0-5 m/min | 0-5 m/min |

| Rapid feed, X- and Z-axis | 8 / 15 m/min | 8 / 15 m/min | 8 / 15 m/min | 8 / 15 m/min |

| Tooling system: Revolver | VDI 30 | VDI 30 | VDI 30 | VDI 30 |

| Number of fixed tool stations/ rotating tool stations | 8 / - | 8 / - | 12 / 6 | 12 / 6 |

| AC motor drive: Power continuous/ intermitten | - | - | 1.1 / 3.7 kW | 1.1 / 3.7 kW |

| Spindle speed, stepless | - | - | 30 - 5000 min¯¹ | 30 - 5000 min¯¹ |

| Maximum tool size | 20 x 20 mm | 20 x 20 mm | 20 x 20 mm | 20 x 20 mm |

| Tailstock | ||||

| Spindle taper (pneumatic) | MORSE 5 | MORSE 5 | MORSE 5 | MORSE 5 |

| External diameter of the spindle (pneumatic) | 72 mm | 72 mm | 72 mm | 72 mm |

| Spindle stroke (pneumatic) | 80 mm | 80 mm | 80 mm | 80 mm |

| Adjustable pressing force (pneumatic) | 25 - 440 daN | 25 - 440 daN | 25 - 440 daN | 25 - 440 daN |

| Spindle taper with starwheel | MORSE 5 | MORSE 5 | - | - |

| External diameter of the spindle | 72 mm | 72 mm | - | - |

| Spindle stroke with starwheel | 225 mm | 225 mm | - | - |

| Coolant supply | ||||

| Tank capacity | 120 L. | 120 L. | 120 L. | 120 L. |

| Pump displacement capacity | 8 L/min | 8 L/min | 8 L/min | 8 L/min |

| Pressure of waterning pump | 5 bar | 5 bar | 5 bar | 5 bar |

| Dimensions and weight | ||||

| Approximate net weight of the machine | 2,640 kg | 2,640 kg | 2,740 kg | 2,740 kg |

| Overall dimensions in mm length x depth x height | 2,301 x 1,460 x 1,676 mm | 2,301 x 1,460 x 1,676 mm | 2,301 x 1,460 x 1,676 mm | 2,301 x 1,460 x 1,676 mm |

-The 180 CCN High Precision Lathes are in conformity with the European Community safety regulations. In view of the constant improvements made to our products, technical data illustrations, dimensions, and weights appearing in this catalogue are subject to change without notice.