Ultra Precision Products

102 TM-CNC

Turn Mate

Hard Turning

Automation Turning

High-precision lathes with numerical control by Fanuc. Like a conventional lathe, these machines can be operated by means of handwheels or they can be controlled numerically. The Turn Mate function is very easy to use and does not demand ISO programming knowledge. Equipped with W25 collet.

- Thread cutting up to 2,000 rpm

- Grooving with radius or chamfers

- Free figure (max. 30 blocks)

- Programming in ISO

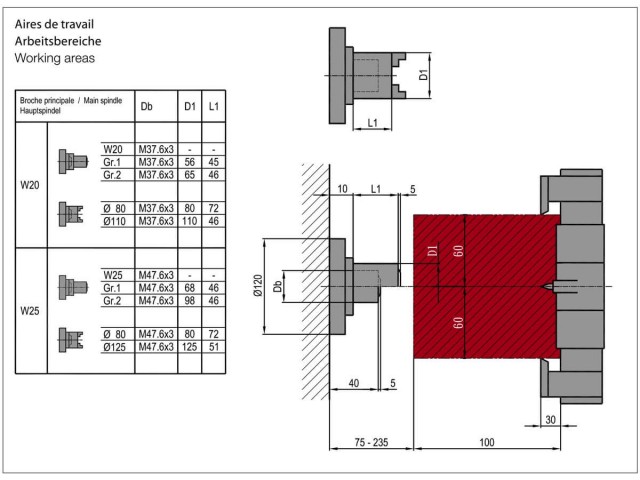

Working Areas

The working areas of main spindle W20/ W25 of 102 TM-CNC.

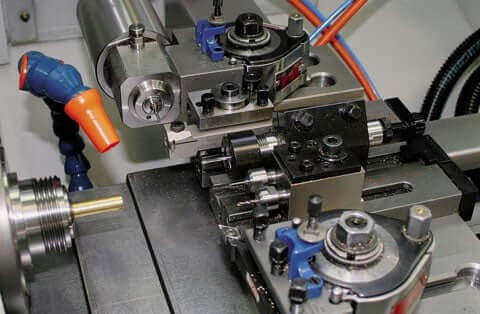

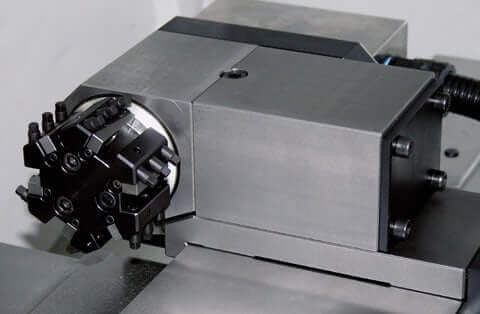

Turret only on 102 TM-CNC with Fanuc 0i Mate-TD

Increase the capacity of tooling of the machine which allows to produce complex parts in 1 clamping.

Turret Technical Data

The turret is 6 fixed positions and contollred by the control of the machine. However, the turret can only be installed on the back side of the carriage.

| ITEM | 102 TM CNC | |||||

|---|---|---|---|---|---|---|

| Machining Capacity | ||||||

| Height of centers over bed | 102 mm | |||||

| Height of centres over carriage | 40 mm | |||||

| Maximum turning diameter | 200 mm | |||||

| Maximum swing over carriage | 75 mm | |||||

| Turning length with collets | W20: 100 mm/ W25: 100 mm | |||||

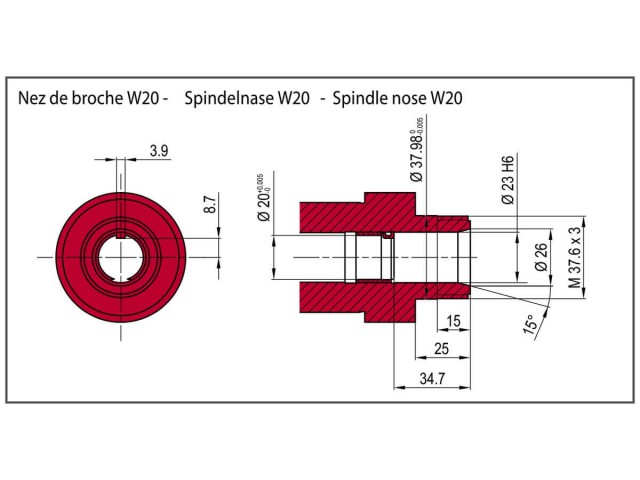

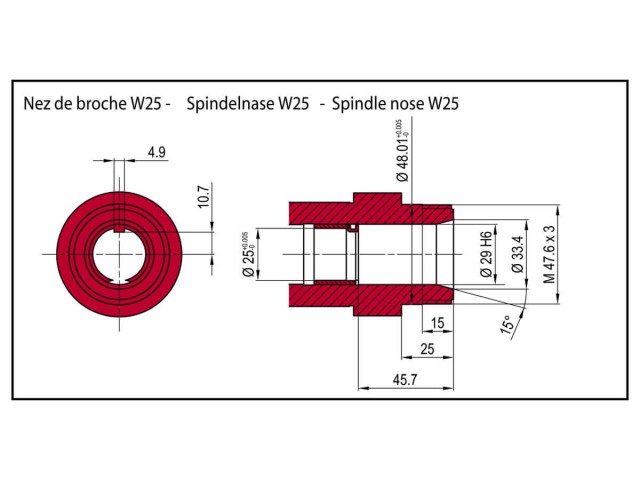

| Headstock | ||||||

| Spindle for SCHAUBLIN collets | W20 / W25 | |||||

| Spindle speed | 50 - 8000 min-1 | |||||

| AC motor drive:Power continuous/ intermittent | 1.5/2.2 kW | |||||

| Programmable increment | 0.001° | |||||

| Spindle throughbore (without drawbar) | 17mm / 21mm | |||||

| Spindle throughbore with collet | W20:14.5 mm / W25:19 mm | |||||

| Carriage | ||||||

| Transverse stroke, X-axis | 120 mm | |||||

| Resolution, X axis (on-radius) | 0.0005 mm | |||||

| AC motor drive: Continuous/ intermittent torque | 0.65 Nm / 2.5 Nm | |||||

| Longitudinal stroke, Z-axis | 100 mm | |||||

| Resolution, Z- axis | 0.001 mm | |||||

| AC motor drive,continuous / intermittent torque | 0.65 Nm / 2.5 Nm | |||||

| Feeds | ||||||

| Working feeds, X- and Z-axis, stepless | 0-5 m/min | |||||

| Rapid feed, X- and Z-axis | 7 m/min | |||||

| Tooling system: Linear | ||||||

| Number of radial toolholder(according to Ø of the piece) | 2 | |||||

| Number of frontal toolholder(according to Ø of the piece) | 2~5 | |||||

| Maximum tool size(MULTIFIX / TRIPAN / SMSA) | 12 x 12 mm | |||||

| Milling and Grinding attachment (options) | Yes | |||||

| Clamping tools for collets | ESX 20 / ESX 9 | |||||

| Screw-type tailstock | ||||||

| Internal taper of the sleeve | MORSE 2 (Option) | |||||

| Spindle OD | 30 mm | |||||

| Spindle stroke | 80 mm | |||||

| Tank with coolant(Option) | ||||||

| Tank capacity | 25 l. (option) | |||||

| Pump displacement capacity | 10 l/min (option) | |||||

| Pressure of waterning pump | 0.5 bars (option) | |||||

| Dimensions and weight | ||||||

| Approximate net weight of the machine | 700 kg | |||||

| Load floor | 1,893 kg/m² | |||||

| Overall dimensions in mm length x depth x height | 1,400 x 880 x 1,470 mm | |||||

-The 102 TM-CNC High Precision Lathes are in conformity with the European Community safety regulations. In view of the constant improvements made to our products, technical data illustrations, dimensions, and weights appearing in this catalogue are subject to change without notice.