Ultra Precision Products

842/Mi

CNC Turning

The perfect high-precision machine for complex applications, also suitable for hard turning Our machines are manufactured around a rigid structure, and can be modified to suit your specific area of use. A number of different versions are available, including the standard version with a 16-position frontal VDI 30 turret. The top-of-the-range version includes an integrated spindle and a high precision 12-position turret. A counter spindle and tailstock are available as options.

- The front turret is a VDI 30 turret

- Front turret has 16 stations that are all driven

- High precision production lathe with FANUC digital control

- Turret speed up to 12,000 rpm

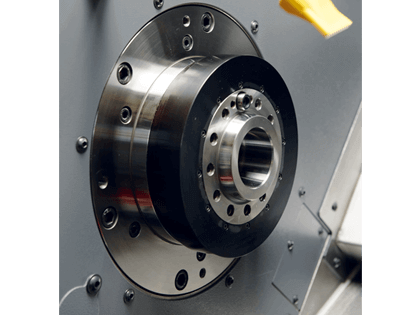

High Precision Spindle

The high-precision main spindle features a high torque and performance characteristics. Optionally, the sub-spindle enables parts to be finished while perfect coaxiality is guaranteed.

Fanuc ultra-performancce systems

We cooperate with partners renowned all over the world. Fanuc offers ultra-performancce systems tailored to the specific requirements.

High-precision radial turret

The high-precision radial turret can be used for main spindle and sub-spindle operations. The 12 turret stations are driven by an integrated motor designed for speeds up to 12,000 rpm.

| 842 | 842 Mi | |||||

|---|---|---|---|---|---|---|

| Machining Capacity | ||||||

| Maximum turning diameter | 300 mm | 300 mm | ||||

| Stroke X | 400 mm | 400 mm | ||||

| Max. distance between centers | 470 mm | 450 mm | ||||

| Max. distance between spindle noses | - | 642 mm | ||||

| Headstock | ||||||

| ISO spindle nose | A2-5 | A2-5 | ||||

| Max. throughbore | 42 mm | 42 mm | ||||

| Moteur C axis | Déporté | Intégré | ||||

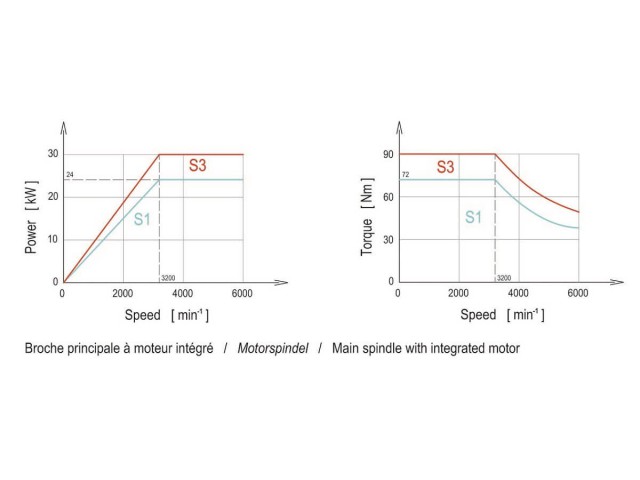

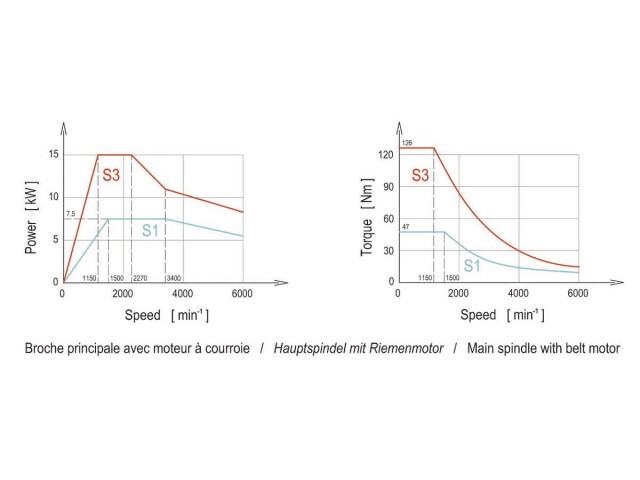

| Power continuous / intermittent | 7.5 kW / -15 kW | 24 kW / 30 kW | ||||

| Torque continuous/ intermittent | 47 Nm / 126 Nm | 72 Nm / 90 Nm | ||||

| Rotational speed range | 50 - 6’000 min-1 | 50 - 6’000 min-1 | ||||

| Adjustable axial clamping force S1 hydraulic | 5’000 - 33’000 N | 5’000 - 33’000 N | ||||

| Counter Spindle (option) | ||||||

| ISO Spindle nose | - | A2-4 | ||||

| Max. throughbore | - | 32 mm | ||||

| Moteur avec axe C | - | Déporté | ||||

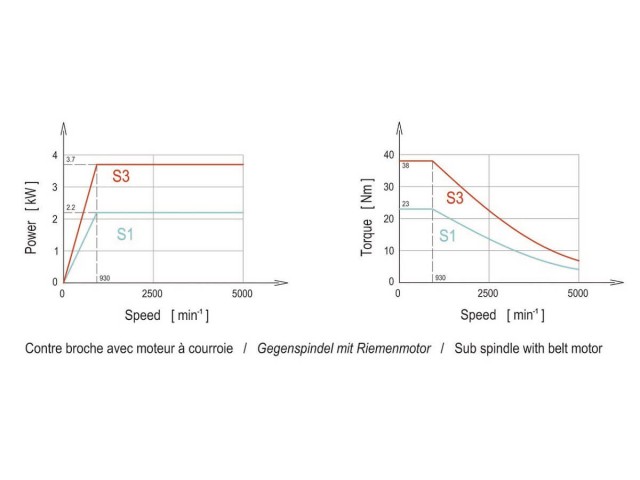

| Power continuous/intermittent | - | 2.2 kW / 3.7 kW | ||||

| Torque continuous/intermittent | - | 23 Nm / 38 Nm | ||||

| Rotational speed range | - | 50 - 5’000 min-1 | ||||

| Adjustable axial clamping force S2 pneumatic | - | 4’500 - 11’500 N | ||||

| Turret | ||||||

| Tool clamping | VDI 30 Fronta | SAUTER Radial | ||||

| Number of tool stations(all driven) | 16 | 12 | ||||

| Maximum tool size | 20 x 20 mm | 20 x 20 mm | ||||

| Torque of the rotating tools, S1 | 9 - 14.2 Nm (1600 min-1) | 4 - 8 Nm (6000 min-1) | ||||

| Power continuous/intermittent | 2 kW / 8 kW | 3 kW / 6 kW | ||||

| Indexing time 1 pos. | 0.56 s | 0.39 s | ||||

| Slide Upper Turret | ||||||

| Stroke X / Z | X = 200 / Z = 400 mm | X = 200 / Z = 400 mm | ||||

| Feedrate X / Z | 30 m/min max | 30 m/min max | ||||

| Resolution X | 0.00005 | 0.00005 | ||||

| Resolution Z | 0.0001 | 0.0001 | ||||

| Slide Counter-Spindle (Option) | ||||||

| Stroke Z | - | 445 mm | ||||

| Feedrate Z | - | 30 m/min max | ||||

| Resolution E | - | 0.0001 | ||||

| Contre-pointe cône morse 3 (option) | ||||||

| Stroke Z | 445 mm | 445 mm | ||||

| Feedrate Z | 30 m/min max | 30 m/min max | ||||

| Tank with Coolant | ||||||

| Tank capacity | 170 L. | 170 L. | ||||

| Pump displacement capacity | 42 L/min à 19m | 42 L/min à 19m | ||||

| Pressure of watering pump | 10 bar | 10 bar | ||||

| Dimensions and Weight | ||||||

| Approximate net weight of the machine | 3,300 kg | 3,600 kg | ||||

| Overall dimensions in mm L x D x H | 1,895 x 1,783 x 1,947 mm | 1,895 x 1,783 x 1,947 mm | ||||

The 842 High Precision Lathes are in conformity with the European Community safety regulations (CE). In view of the constant improvements made to our products, technical data, illustrations, dimensions and weights appearing in this catalogue are subject to change without notice.