Vertical Machining Center

NV700/850/1000

Mold

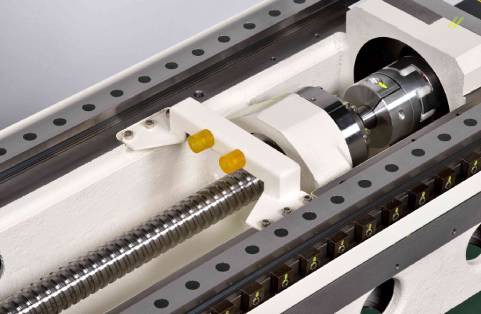

The NV Series improved the rigidity by employing wider guideways, C2 pretension ball screw offers superior damping performance with roller linear guide in all axes.

The NV Series feature the high value for contributing more operation profit for customers, suitable to small, medium and larger size parts with larger work envelope and less floor.

- Spindle speed 12,000 rpm/ 15,000 rpm/ 24,000 rpm variations to meet a wide range of machining needs.

- Faster swing arm type ATC with tool capacity 24 standard or 30 tools optional for more versatile applications.

- Pressurized coolant washdown and a high-volume coolant tank ensure the smooth flow of coolant and chips, effectively minimizing cutting heat.

- Experienced FEA technology.

Collision Protection System

The equipment is furnished with a collision protection system that can reduce the effects of impacts arising from mechanical malfunctions or mistakes made by operators. This safeguard mechanism efficiently limits the extent of impairment caused by collisions, all the while maintaining the desired levels of precision in the design.

Ultra Precision Linear Encoder (Opt.)

The X/Y/Z axis can be equipped to integrate a linear scale system, allowing for the dectection of thermal changes caused by machine rapid movement. The resultant thermal displacement data is then transmitted to the controller for adjustment, particularly beneficial for machining high-precision components.

Larger Work Range

A substantial column with robust ribs and expanded guide ways contribute to a soild framework, ensuring limited overhang and improved distribution of cutting forces. The machines' structure composition, utilizing Meehanite cast iron and an improved rib arrangement, guarantees the highest level of stability.

| No | Group | ITEM | NV700 | NV850 | NV1000 |

|---|---|---|---|---|---|

| 1 | Working Range | Travel X/Y/Z | 710/400/450 mm | 850/510/510 mm | 1,020/560/560 mm |

| 3 | Table Size | 850 x 400 mm | 1,020 x 500 mm | 1,020 x 550 mm | |

| 4 | Table Load Capacity | 500 kg | 700 kg | 900 kg | |

| 7 | Main Spindle | Max. Spindle Speed | 12,000/ (15,000/ 24,000) rpm | ||

| 11 | Feed Drive | Rapid Travel X/ Y/ Z | 36/ 36/ 36 m/ min | ||

| 14 | Automatic Tool Changer | Tool Selection | Random and shortest selection | ||

| 15 | Magazine Pots | 24 (Opt. 30) | |||

| 16 | Max. Tool adj. w/o Tool | 75/ 150 mm | |||

| 17 | Max. Tool Length | 300 mm | |||

| 18 | Max. Tool Weight | 6 kg | 7 kg | ||

| 19 | CTC Time | 1.8 sec. | 2.5 sec. | 2.8 sec. | |

| 20 | Accuracy ISO 230-2 | Positioning Accuracy | 0.007 mm | ||

| 21 | Repeatability Accuracy | 0.004 mm | |||

| 22 | Straightness | 0.010 mm | |||

| 23 | Squareness | 0.010 mm | |||

| 24 | Coolant System | Coolant Tank Capacity | 200 L | 260 L | 400 L |

| 25 | Nozzle Coolant & Flush Pump | 70L/min 3.1 bar x2 | |||

| 26 | Through Spindle Coolant | 20, 50, 70 bar (Opt.) | |||

| 27 | Lubrication & Cooling | Spindle Lubrication | Grease(Oil Air, Opt) | ||

| 28 | Thermal Cooling | Spindle Cooling | |||

| 29 | Machine Size | Floor Space Height | 2,547 mm | 2,620 mm | 2,747 mm |

| 30 | Floor Space Width | 2,100 mm | 2,200 mm | 2,280 mm | |

| 31 | Floor Space Depth | 2,295 mm | 2,445 mm | 2,615 mm | |

| 32 | Weight | 4,000 kg | 5,200 kg | 5,500 kg | |

| 33 | Connections | Main Power | 20 KVA | 25 KVA | 25 KVA |

| 34 | Pneumatic Consumption | 5.5 kg/ cm2 | |||

*¹Two-faced contact tools are needed for getting better cutting capability.

※Actual values may differ from the specification in the catalog caused by optional and peripheral accessories.