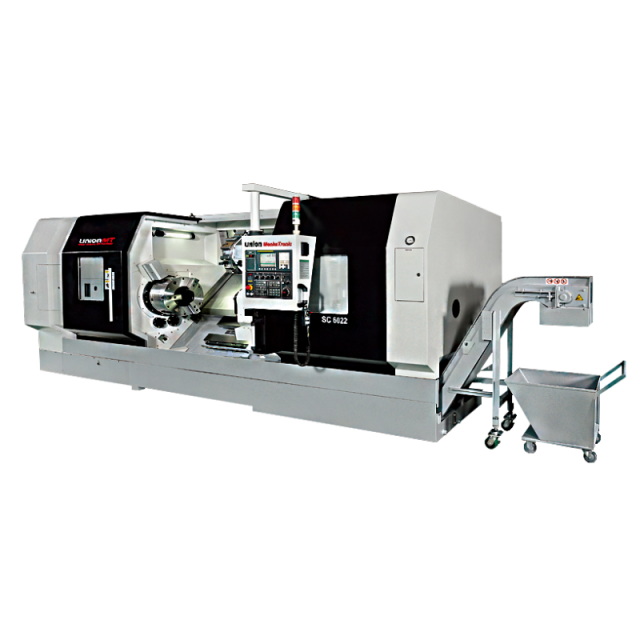

Precision CNC Horizontal Turning Center with Superior Rigidity

Union MT’s CNC Horizontal Turning Centers are engineered for high-performance machining, offering superior rigidity, stability, and flexibility. Designed with a 45-degree slant bed, each turning center ensures easier loading, tool setup, and efficient chip removal. With reinforced structures and optional tool turrets or Y-axis attachments, these machines support simultaneous turning, milling, and drilling—ideal for boosting throughput in horizontal CNC turning operations.

Whether for heavy-duty cuts or precision finishing, Union MT provides a complete CNC horizontal turning center lineup to meet diverse industry needs. These machines are widely applied in equipment manufacturing, metal hardware, and precision CNC turning of critical components, delivering accuracy and productivity for small to medium-sized parts.

Explore Our Horizontal Turning Center Lineup

- SC6000 Series — Compact slant-bed CNC horizontal turning center designed for stability and precision in medium-size part machining.

- SL Series — Flexible turning center with optional Y-axis and power turrets for multi-process machining in one setup.

- SC8000 Series — Heavy-duty horizontal CNC turning solution with reinforced bed and long travel capacity for larger components.

Applications

Union MT horizontal turning centers are widely used in aerospace, automotive, consumer electronics, micro-mechanics, precision mold, and medical industries — delivering efficiency and accuracy across a variety of machining tasks.